Precision machined Stainless Steel Parts: Defying nyuaj nrog HY Hlau CNC Khw

Taw qhia:

Raws li thev naus laus zis nce qib, qhov kev thov rauCNC machined stainless hlau qhov chawnrogsiab zoo, zoo machined tiav, thiab nruj kam rau uatau nce ntau heev. Cov tuam txhab tsim khoom cia siab rau cov noprecision Cheebtsamlos txhim kho kev ua tau zoo thiab kev ntseeg siab ntawm peb cov khoom.

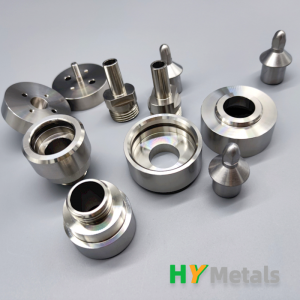

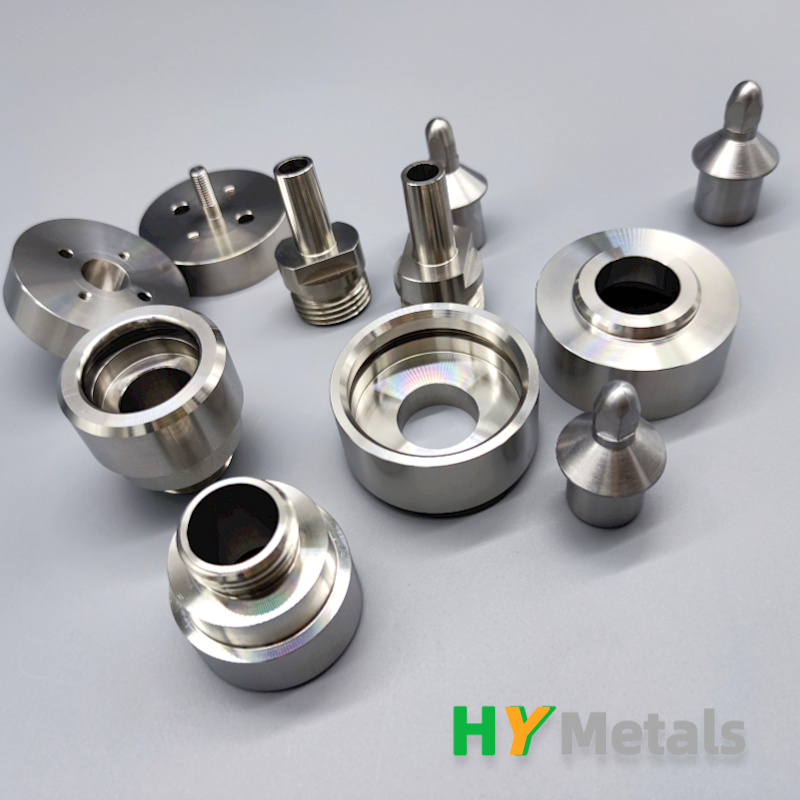

Txawm li cas los xij, stainless hlau tsis muaj npe nrov rau nws qhov nyuaj machinability vim nws hardness thiab cov yam ntxwv tshwj xeeb. Tsab ntawv no yuav ua kom pom tseebHY Hlau CNC khw's kev txawj ntse nyob rau hauv manufacturing tshiab stainless hlau qhov chaw, highlighting peb exceptional muaj peev xwm nyob rau hauvmilling thiab tigcov txheej txheem, ua tiav superior zoo, thiab kev tswj xyuasnruj tolerance.

Machining Stainless hlau: Ib qho yooj yim kos duab:

Kev ua haujlwm nrog cov hlau tsis muaj steel yuav dhau los ua ntau yam nyuaj uas tuaj yeem tsim teeb meem rau kev ua haujlwm machining. Stainless hlau lub hardness thiab kub tsis kam ua rau nws yooj yim rau cov cuab yeej siv ntau dhau, deformation, thiab ua kom tsis zoo. Ntxiv mus, nws lub zog siab thiab qis thermal conductivity yuav tsum tau tshwj xeeb txoj hauv kev kom txo qis thermal distortion thiab xyuas kom meej qhov tseeb.

HY Hlau CNC Khw: Mastering Stainless Hlau Machining:

1. Khoom siv thiab kev txawj ntse:

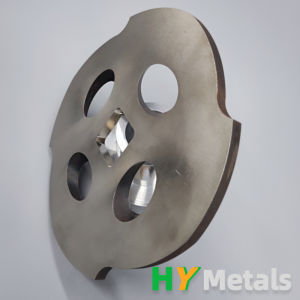

HY Hlau CNC khw muaj lub xeev-of-the-art, computer numerical control (CNC) milling thiabtig tshuabtshwj xeeb tshaj yog haum rau stainless hlau qhov chaw. Peb cov kws paub txog kev siv tshuab muaj qhov kev paub zoo uas yuav tsum tau ua los tswj cov kev ua haujlwm zoo sib xws thiab cov cuab yeej tsim nyog tsim nyog los ua haujlwm nrog stainless hlau zoo.

2. Kev xaiv khoom:

Kev nkag siab txog cov yam ntxwv ntawm cov qib stainless hlau sib txawv yog qhov tseem ceeb. HY Hlau CNC kav khw ua tib zoo xaiv cov qib tsim nyog raws li cov kev xav tau tshwj xeeb, xws li corrosion kuj, lub zog, thiab machinability. Qhov no ua kom pom kev ua tau zoo thiab txhim kho lub neej ntev ntawm cov khoom kawg.

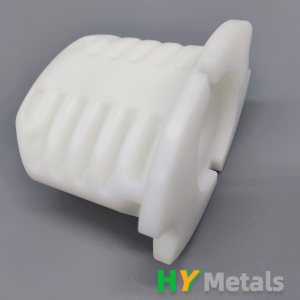

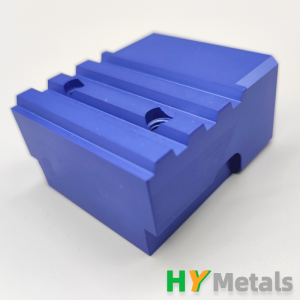

3. Precision Machining:

Lub khw siv cov txheej txheem CNC milling thiab tig cov txheej txheem kom ua tiav qhov ntev thiab cov duab geometry nyuaj. Cov txheej txheem tswj hwm lub khoos phis tawj tso cai rau kev rov ua tau zoo dua qub, ua kom zoo ib yam ntawm ntau qhov chaw. Qhov no precision machining kuj ua kom nruj tolerances, lub rooj sib tham los yog tshaj cov neeg siv khoom specifications.

4.Tooj xaiv thiab optimization:

HY Hlau CNC kav siv cov cuab yeej txiav zoo tsim tshwj xeeb rau kev ua cov hlau tsis zoo. Cov cuab yeej no yog tsim los tiv thaiv cov kev xav tau ntawm stainless hlau machining, txo cov cuab yeej hnav, thiab txo qhov ua yuam kev. Tsis tas li ntawd, lub khw siv cov cuab yeej tshiab txoj kev tswv yim, optimizing txiav tej yam kev mob los txhim kho nto tiav thiab raug.

5.Nto tiav thiab zoo:

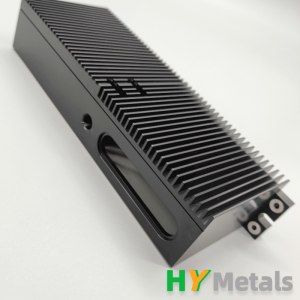

HY Hlau CNC khw muab qhov tseem ceeb rau kev ua tiav qhov tshwj xeeb machined tiav rau stainless hlau qhov chaw. Siv ntau yam txuj ci, xws li precision sib tsoo, polishing, thiab electropolishing, lawv xyuas kom meej du nto, tshem tawm cov imperfections thiab muab ib tug visually txaus nyiam. Qhov kev mloog mus rau kev nthuav dav no txhim kho cov kav ntev thiab kev zoo nkauj ntawm cov khoom siv hlau stainless kawg.

6.Quality Assurance:

Txhawm rau lav cov qauv zoo tshaj plaws, HY Hlau CNC khw ntiav cov kev tswj xyuas zoo. Lawv muaj ib pab neeg soj ntsuam hauv tsev uas siv cov cuab yeej ntsuas ntsuas qib siab, suav nrog cov tshuab ntsuas kev sib koom tes (CMMs), txhawm rau txheeb xyuas qhov ntev, qhov siab ntev, thiab qhov chaw tiav. Qhov no ua kom ntseeg tau tias txhua qhov tsis muaj steel hlau tawm hauv peb qhov chaw ua tau raws li cov neeg siv khoom xav tau.

Xaus:

Los ntawm peb cov kws tshaj lij hauv CNC milling thiab tig, HY Hlau CNC khw tau paub txog kev kos duab ntawm machining stainless hlau qhov chaw nrog siab precision, zoo machined tiav, thiab nruj tolerances. Txawm hais tias muaj kev sib tw los ntawm cov hlau tsis muaj steel, peb cov cuab yeej siv siab heev, kev paub txog cov khoom siv, thiab cov neeg ua haujlwm txawj ua haujlwm pub rau peb kov yeej cov teeb meem no tau zoo. Los ntawm kev siv lub xeev-ntawm-lub-kos duab cov tswv yim thiab tswj nruj zoo tswj kev ntsuas, HY hlau tau tsim nws tus kheej raws li ib tug ntseeg chaw tsim tshuaj paus ntawm superior stainless hlau Cheebtsam.