Peb tseem tuaj yeem muab kev cai hlau ua haujlwm xws li txhuas extrusion thiab tuag-casting. Peb pab neeg ua haujlwm paub txog cov kws tshaj lij thiab cov neeg tsim qauv tuaj yeem pab tsim cov khoom siv nrog cov duab thiab qhov ntau thiab tsawg. Peb tuaj yeem pab koj ua tiav cov txiaj ntsig xav tau ntawm ob qho tib si kev zoo nkauj thiab kev ua haujlwm. Peb siv cov thev naus laus zis thiab cov khoom siv los xyuas kom meej qhov zoo tshaj plaws ntawm cov khoom thiab cov khoom.

Peb muab cov nqi sib tw thiab lub sijhawm hloov pauv sai. Tiv tauj peb hnub no los tham txog koj txoj haujlwm kev cai hlau ua haujlwm.

Aluminium Extrusion

Lub tsev thiab kho kom zoo nkauj ntawm cov txheej txheem aluminium profiles muaj ntau heev hauv peb lub khw hauv zos.

HY Metals tsis yog nyob rau hauv qhov qauv profile cheeb tsam.

Peb tshwj xeeb hauv kev cai txhuas extrusion lossis aluminium profile uas feem ntau siv hauv peb cov khoom los pab CNC machining txheej txheem ntau pheej yig dua.

Rau qee qhov tshwj xeeb zoo ntawm lub tshuab hluav taws xob lossis qee qhov kev hloov kho aluminium kuj tuaj yeem raug extruded ces machined rau cov duab kos.

Raws li ntev raws li nws yog tib seem rau qee qhov ntim qis lossis ntau lawm aluminium machined qhov chaw, peb tuaj yeem ua rau lawv los ntawm extrusion ces CNC machining txheej txheem kom txuag tau sijhawm thiab nqi machining.

Kev cai extrusion yuav xav tau cov cuab yeej extrusion ua ntej. Cov cuab yeej feem ntau tsis kim heev piv nrog cov casting lossis txhaj pwm.

Daim duab 2: Qee qhov kev cai txhuas extrusion qhov chaw los ntawm HY Hlau

Piv txwv li, qhov kawg 3 raj hauv daim duab no tau extruded ib lub raj tshwj xeeb ntev ua ntej thiab tom qab ntawd tshuab lub qhov thiab txiav tawm raws li daim duab kos. Peb tau ua cov cuab yeej extrusion rau qhov no vim tias tsis muaj qhov loj thiab zoo li lub raj hauv khw.

Extrusion + CNC machining yog qhov kev daws teeb meem zoo tshaj plaws rau qhov no.

Tuag Casting

Tuag casting yog txheej txheem hlau casting, uas yog tus cwj pwm los ntawm kev siv pwm kab noj hniav los thov kev kub siab ntawm cov hlau molten. Tuag rau casting los yog hu ua Pwm ntawm casting feem ntau yog ua los ntawm cov alloys muaj zog.

Hlau Tuag casting zoo ib yam li kev txhaj tshuaj molding. Cov khoom siv tuag casting feem ntau yog hlau tsis muaj hlau, xws li zinc, tooj liab, txhuas, magnesium, txhuas, tin, thiab txhuas-tin alloys.

Daim duab 3: Tuag Casting Part.

Cov txheej txheem tuag-casting feem ntau yog siv los tsim cov khoom loj rau QTY loj nrog me me thiab nruab nrab vim tias cov pwm pwm siab. Piv nrog rau lwm cov txheej txheem casting, tuag casting muaj qhov flatter nto thiab ntau dua qhov sib xws.

Nyob rau hauv peb precision hlau ua hauj lwm, peb feem ntau ua tuag-casting qhov chaw ces CNC machined kom tau tiav qhov chaw.

Hlau txoj kev thiab caij nplooj ntoos hlav

Hlau txoj kev thiab springs kuj yog ib tug heev txheej txheem rau ntau yam kev lag luam tej yaam num.

Peb tuaj yeem ua txhua yam ntawm cov hlau sib sau xws li steel, stainless hlau, tooj liab.

Daim duab 4: Hlau tsim qhov chaw thiab cov springs los ntawm HY Hlau

Khiav

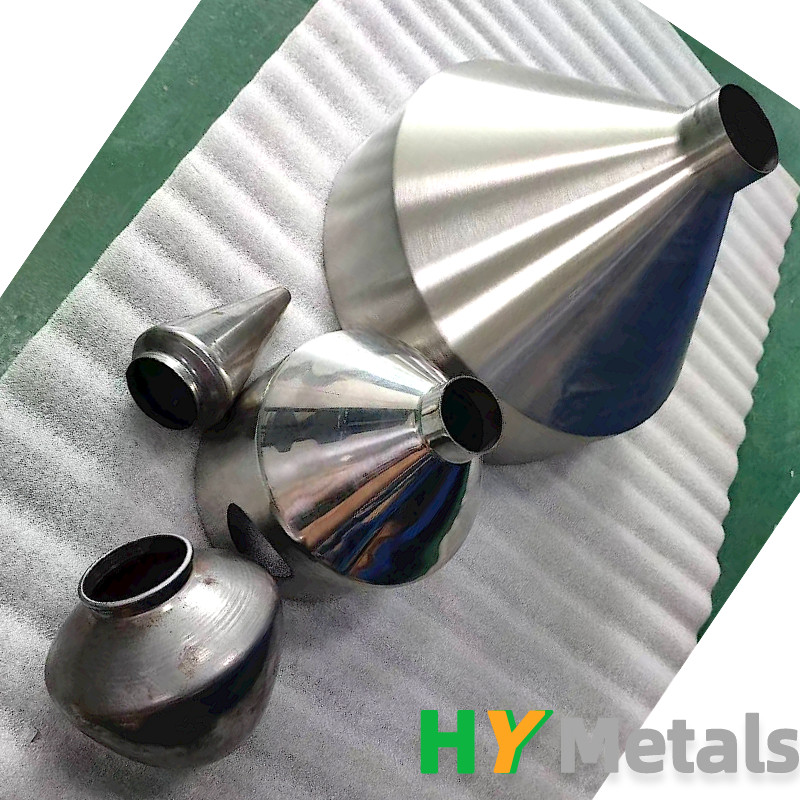

Spinning yog muab cov phaj tiaj tus lossis cov khoom siv hollow rau ntawm axis spindle ntawm spinning tshuab los ua cylindrical, conical, parabolic tsim los yog lwm yam nkhaus. Rotating qhov chaw ntawm cov duab zoo heev tuaj yeem ua tiav los ntawm kev sib tw.

Daim duab 5: Qee cov khoom Spinning los ntawm HY Hlau

Vim tias qhov kev ua siab ntev ntev, Spinning txheej txheem siv tsawg dua hauv peb cov khoom.

Qee lub sij hawm peb cov neeg muas zaub hauv cov rooj tog zaum lossis teeb pom kev lag luam txiav txim lub teeb npog los ntawm peb. Peb feem ntau ua cov npog los ntawm spinning.