Flatness yog ib qho tseem ceeb geometric kam rau ua hauv machining, tshwj xeeb tshaj yog rau cov ntawv hlau thiab CNC machining txheej txheem. Nws hais txog qhov xwm txheej uas txhua lub ntsiab lus ntawm ib qho chaw sib npaug ntawm lub dav hlau siv.

Kev ua tiav flatness yog qhov tseem ceeb rau cov laj thawj hauv qab no:

1. Kev Ua Haujlwm Zoo:Feem ntau cov khoom yuav tsum haum ua ke precisely. Yog tias cov khoom tsis tiaj tus, nws tuaj yeem ua rau misalignment thiab cuam tshuam rau tag nrho kev ua haujlwm ntawm kev sib dhos.

2. Load Distribution:Flat deg kom ntseeg tau tias txawm thauj khoom faib. Qhov chaw tsis sib xws tuaj yeem ua rau muaj kev ntxhov siab ntau uas tuaj yeem ua rau lub cev tsis ua haujlwm ntxov ntxov.

3. Aesthetic Quality:Hauv kev lag luam uas zoo li tseem ceeb, xws li tsheb thiab cov neeg siv khoom siv hluav taws xob, flatness pab txhim kho qhov pom kev pom ntawm cov khoom.

4. Kev sib dhos ua haujlwm:Cov khoom tsis sib xws tuaj yeem cuam tshuam cov txheej txheem sib dhos, ua rau cov nqi zog thiab sijhawm ntau ntxiv.

5. Precision rau ntxiv machining:Flatness feem ntau yog qhov yuav tsum tau ua ua ntej rau kev ua haujlwm tom ntej xws li drilling lossis milling, qhov chaw tiaj tus yog tsim nyog kom tau txais cov txiaj ntsig raug.

Ua kom flatness thaum ua

Kev ua tiav thiab kev tswj kom tiaj tus thaum lub sijhawm ua haujlwm yuav tsum tau ua tib zoo npaj thiab ua tiav. Nov yog qee cov tswv yim:

1. Kev xaiv cov khoom siv:Xaiv cov ntaub ntawv uas tsis yooj yim rau warp lossis deform thaum ua. Cov hlau nrog qis coefficients ntawm thermal expansion feem ntau nyiam.

2. Kho kom raug Fixtures:Siv cov khoom tsim nyog los tuav lub workpiece kom ruaj ntseg thaum lub sij hawm machining. Qhov no txo qis kev txav thiab kev co uas tuaj yeem ua rau warping.

3. Tswj machining tsis:Optimize txiav ceev, pub thiab qhov tob ntawm txiav. Cov cua kub ntau dhau thaum ua tiav tuaj yeem ua rau thermal expansion thiab warping.

4. Sequential Machining:Yog tias ua tau, tshuab qhov chaw hauv theem. Qhov no tso cai rau cov khoom raug tshem tawm raws li kev tswj hwm, txo qhov kev pheej hmoo ntawm deformation.

5. Kev kho mob tom qab ua tiav:Xav txog cov txheej txheem kev ntxhov siab xws li kev ua haujlwm tom qab annealing lossis normalizing kom tshem tawm cov kev ntxhov siab sab hauv uas yuav ua rau muaj kev sib ntaus sib tua.

6. Kev Siv Lub Plawv Reference Surface:Tsis tu ncua xyuas thiab ntsuas cov cuab yeej siv tshuab kom ntseeg tau tias lawv tau khiav ntawm qhov chaw tiaj tus.

Xyuas flatness

Kom paub meej tiasmachined qhov chawUa tau raws li cov kev qhia tshwj xeeb, kev tshuaj xyuas tsim nyog yuav tsum tau siv:

1. Kev tshuaj xyuas qhov muag:Kev tshuaj xyuas qhov muag pom tau yooj yim tuaj yeem qee zaum qhia pom qhov teeb meem flatness, xws li qhov khoob hauv ib feem lossis lub teeb hla.

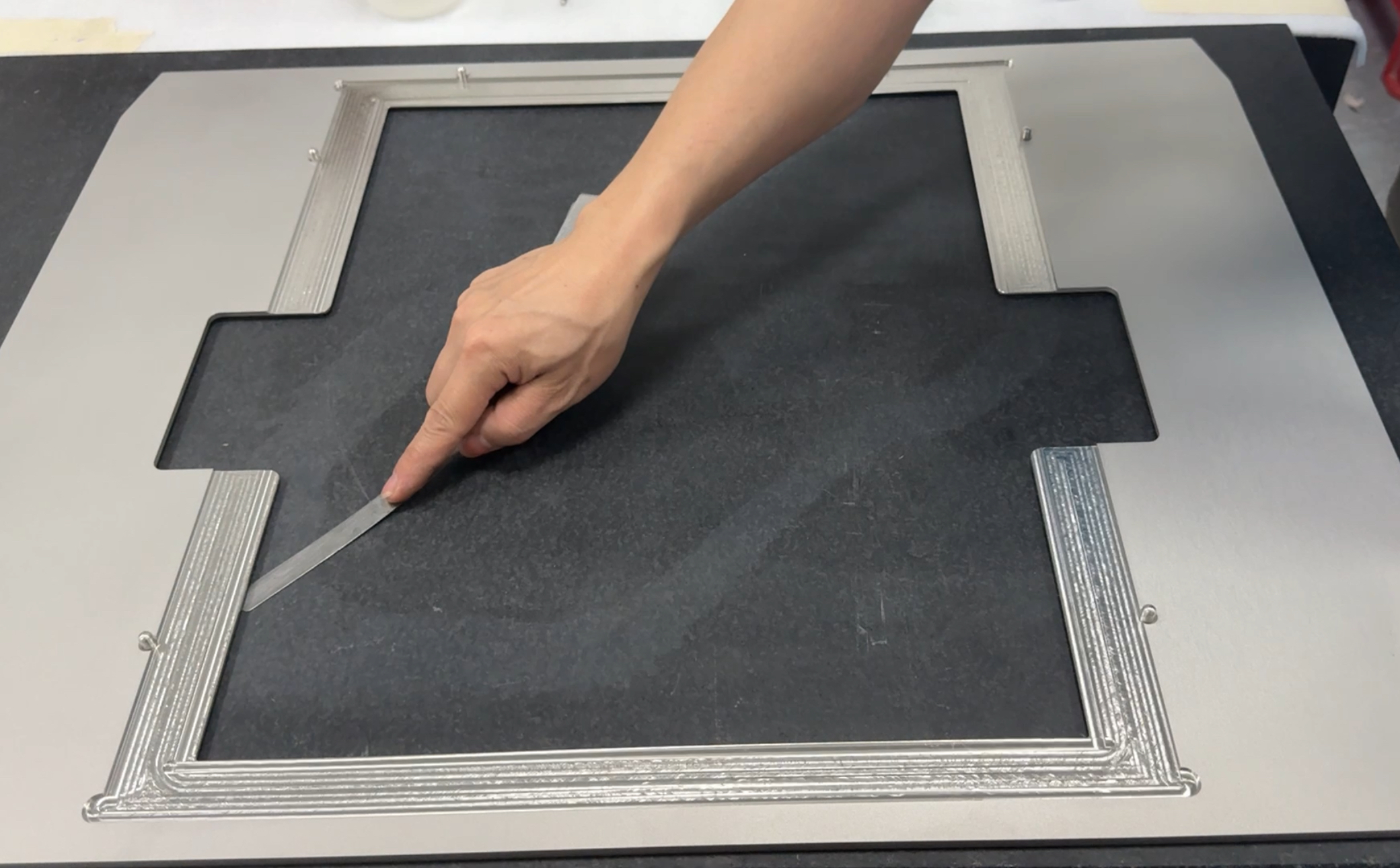

2. Tus Txheej Txheem:Muab tus pas ntsuas qhov tseeb rau ntawm qhov chaw thiab siv lub ntsuas ntsuas ntsuas ntsuas qhov khoob. Txoj kev no zoo heev rau kev soj ntsuam ceev.

3. Dial qhia:Lub dial taw qhia yuav siv tau los ntsuas qhov flatness sib txawv ntawm tag nrho cov nto. Txoj kev no muab kev ntsuas ntau dua.

4. Coordinate Measuring Machine (CMM):Rau cov ntawv thov siab, CMM tuaj yeem siv los ntsuas qhov flatness ntawm qhov chaw los ntawm kev siv ntau lub ntsiab lus thiab suav qhov sib txawv ntawm lub dav hlau siv.

5. Optical Plane Method:Qhov no suav nrog kev siv lub dav hlau kho qhov muag thiab lub teeb monochromatic los xyuas qhov flatness. Cov qauv cuam tshuam tuaj yeem qhia qhov sib txawv.

6. Laser Scanning:Advanced laser scanning thev naus laus zis muab cov ncauj lus kom ntxaws daim duab qhia chaw, tso cai rau kev tsom xam ntawm flatness.

Hauv kev xaus

Flatness yog ib qho tseem ceeb ntawm kev ua, cuam tshuam rau kev ua haujlwm, kev zoo nkauj thiab kev ua haujlwm sib dhos. Los ntawm kev nkag siab txog nws qhov tseem ceeb thiab siv cov tswv yim los tswj thiab tshuaj xyuas flatness,HY METALS tuaj yeem ua kom ntseeg tau tias cov khoom siv zoo tshaj plaws uas ua tau raws li kev ua haujlwm nruj. Kev tshuaj xyuas tsis tu ncua thiab ua raws li kev coj ua zoo tshaj plaws yuav txhim kho cov khoom lag luam thiab kev txaus siab rau cov neeg siv khoom.

HY Hlaumuabib-nres kev pabcuam kev tsim khoom suav nrog sheet hlau fabricationthiabCNC machining,14 xyoo kev paubthiab8 tag nrho cov khoom siv.

Zoo heevZootswj, luvkev hloov pauv,zoo heevkev sib txuas lus.

Xa kojRFQ nrogcov duab kos duab ntxaws hnub no. Peb yuav hais rau koj ASAP.

WeChat:ib 09260838

Qhia:+86 15815874097

Email:susanx@hymetalproducts.com

Post lub sij hawm: Oct-10-2024