Precision Sheet Hlau txoj kevthiab Simplified Tooling Design: Ib qho txiaj ntsig zoo rau cov qauv thiab cov khoom me me

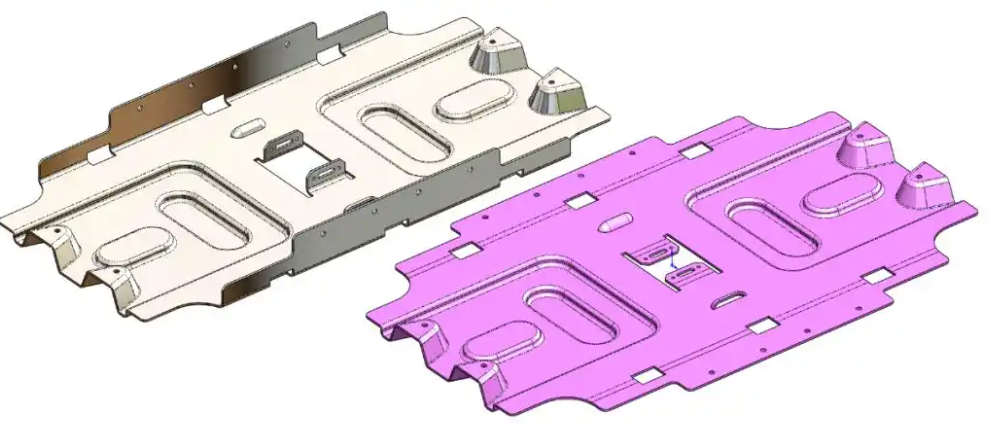

Nyob rau hauv lub realm ntawmsheet hlau fabrication, precision tsimthiabcuab yeej tsimyog qhov tseem ceeb rau kev tsim cov khoom sib txuam nrog cov yam ntxwv tshwj xeeb. Ntawm HY Metals,peb tshwj xeeb hauv kev tsim cov ntawv precision hlau prototypes thiab me me-batch qhov chaw nrog intricate geometry, xws li dimples (凸包), txhawb cov tav (加强筋), thiab complex nkhaus nto feem ntau pom nyob rau hauv automotive daim ntaub ntawv. Peb cov kws tshaj lij hauv cov cuab yeej yooj yim (luv-run tooling or prototype tooling) Kev tsim qauv tso cai rau peb xa cov txiaj ntsig zoo thaum txuag cov neeg siv khoom tus nqi ntawm cov khoom kim heev steel pwm.

——————————————————————————————

Kev sib tw hauv Precision Sheet Hlau txoj kev

1. Complex Geometry:

Cheebtsam uas muaj cov yam ntxwv zoo li dimples los yog reinforcing ribs xav tau meej tswj cov khoom ntws thiab deformation. Kev ua tiav cov txiaj ntsig zoo ib yam tsis muaj qhov tsis xws li tawg lossis wrinkling yog qhov nyuaj.

2. Tswj qhov tseeb:

Kev tuav nruj nruj nyob rau hauv precision sheet hlau sib sau yog qhov tseem ceeb, tshwj xeeb tshaj yog rau cov khoom uas muaj qhov nkhaus nkhaus. Txawm tias me me sib txawv tuaj yeem cuam tshuam kev haum thiab kev ua haujlwm.

3. Tooling Tsim:

Cov cuab yeej yooj yim yuav tsum yog ob qho tib si tus nqi-zoo thiab ua haujlwm, ntsuas qhov yooj yim ntawm kev tsim khoom nrog lub peev xwm ua tiav daim ntawv xav tau. Qhov no yuav tsum muaj kev tsim kho tshiab thiab nkag siab tob txog kev coj cwj pwm ntawm cov khoom siv.

——————————————————————————————

Kev txiav txim siab tsim qauv tseem ceeb rau Cov Cuab Yeej Yooj Yim (cov cuab yeej luv luv)

1. Kev xaiv cov khoom siv:

Kev xaiv cov khoom siv yog nyob ntawm qhov ntim ntau lawm thiab qhov nyuaj ntawm qhov. Rau cov qauv thiab cov khoom me me, cov khoom siv xws li txhuas lossis cov resin feem ntau yog siv los txo cov nqi thiab cov sij hawm txhuas.

2. Tooling Form:

Cov cuab yeej yooj yim tuaj yeem siv ntau hom, xws li cov khoom siv tuag, cov cuab yeej mos, lossis 3D-printed pwm. Cov cuab yeej no tau tsim los ua kom yooj yim rau kev tsim khoom thiab kho, kom ntseeg tau yooj yim rau cov haujlwm sib txawv.

3. Precision thiab Repeatability:

Txawm tias nrog cov cuab yeej yooj yim, kev tswj xyuas qhov tseeb yog qhov tseem ceeb. Peb cov engineers siv cov software siab tshaj CAD / CAM los tsim cov cuab yeej uas ua kom cov txiaj ntsig zoo sib xws thoob plaws ntau qhov kev tsim khoom.

——————————————————————————————

HY Metals 'Kev txawj ntse hauv Kev Tsim Cov Cuab Yeej Yooj Yim

Ntawm HY Metals, peb muaj ib pab neeg ua haujlwm ntawm cov cuab yeej tsim qauv thiabsheet hlau tsim engineersuas ua haujlwm ze nrog cov neeg siv khoom los tsim cov kev daws teeb meem zoo rauprecision sheet hlau txoj kev. Nov yog qhov peb ua tau zoo:

1. Ceev Prototyping:

Rau sheet hlau prototypes, peb tsim thiab tsim cov cuab yeej yooj yim uas tso cai rau kev nrawm nrawm thiab sim. Txoj hauv kev no txo cov sijhawm txhim kho thiab cov nqi, ua rau cov neeg siv khoom siv tau cov qauv tsim ua ntej cog lus rau kev siv cuab yeej.

2. Small-Batch Production:

Rau kev txiav txim me me, peb cov cuab yeej siv yooj yim yog qhov zoo tagnrho. Lawv muab cov precision thiab sib xws uas yuav tsum tau rau qhov chaw nrog dimples, reinforcing ribs, los yog complex curved nto, tsis muaj tus nqi siab ntawm steel pwm.

3. Kev daws teeb meem:

Txhua qhov project yog qhov tshwj xeeb, thiab peb cov engineers txiav cov cuab yeej tsim kom tau raws li cov kev xav tau tshwj xeeb. Seb nws yog precisionsheet hlau tivthaivrau kev lag luam tsheb lossis cov qauv kev cai rau cov khoom siv hluav taws xob, peb xa cov kev daws teeb meem uas ua haujlwm.

————————————————————————————

Qhov zoo ntawm Simplified Tooling

- Kev txuag nyiaj:Los ntawm kev zam qhov kev siv nyiaj ntawm cov pwm steel, cov neeg siv khoom tuaj yeem txo cov nqi ua ntej.

- Faster Turnaround:Cov cuab yeej yooj yim tuaj yeem tsim thiab tsim tau sai, ua rau lub sijhawm luv luv.

- Flexibility:Kev hloov kho rau cov cuab yeej tuaj yeem ua tau yooj yim, tso cai rau kev hloov pauv lossis kev txhim kho thaum lub sijhawm prototyping.

————————————————————————————

Xaus

Precision sheet hlau sib sauthiab simplified tooling tsim yog qhov tseem ceeb rau kev tsimzoo prototypesthiab me-batch qhov chaw nrog complex geometry. Ntawm HY Metals, peb pab pawg kws tshaj lij engineers siv cov cuab yeej tsim kho tshiab thiab cov txheej txheem tshiab los tsim cov cuab yeej siv tau zoo, ua tau raws li cov qauv siab tshaj plaws ntawm qhov tseeb thiab zoo.

Txawm koj xav tausheet hlau prototypes or me-batch ntau lawm of kev cai sheet hlau qhov chaw, HY Hlau yog koj tus khub ntseeg siab. Cia peb pab koj coj koj cov qauv tsim rau lub neej nrog kev ua haujlwm, raug, thiab txuag nqi. Tiv tauj peb hnub no kom paub ntau ntxiv txog pebsheet hlau fabricationthiab cov cuab yeej tsim muaj peev xwm!

HYHlaumuabib-nreskev pabcuam kev tsim khoomsuav nrogsheet hlau fabricationnthiabCNC machining,14 xyoo kev paubthiab8 tag nrho cov khoom siv.

Zoo heev Quality Control,luv turnaround, kev sib txuas lus zoo heev.

Xa kojRFQnrogcov duab kos duab ntxawshnub no. Peb yuav hais rau koj ASAP.

WeChat:ib 09260838

Qhia:+86 15815874097

Email:susanx@hymetalproducts.com

Post lub sij hawm: Feb-13-2025