Knurling yog dab tsi?

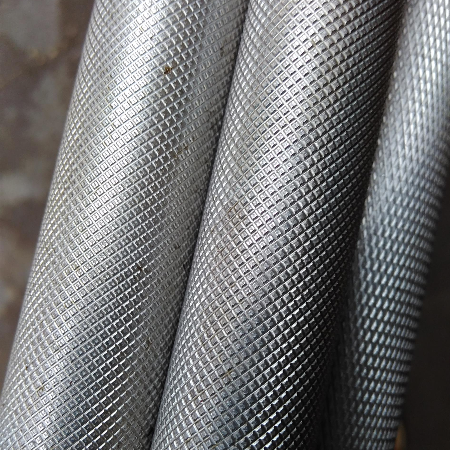

Knurling yog txheej txheem tseem ceeb rauprecision tig ib feems, muab ib tug textured nto uas txhim khu kev tuav thiab zoo li. Nws yuav tsim ib tug qauv ntawmncaj, lub kaum sab xis or pob zeb diamond-zoo li tuskab ntawm qhov chaw ntawm lub workpiece, feem ntau yog siv lub tshuab dhos lossis knurling cuab yeej. Cov txheej txheem yog qhov tseem ceeb rau ntau yam kev siv, suav nrogautomotive, aerospace thiab kev kho mob kev lag luam, qhov twg precision thiab functionality tseem ceeb heev.

Cov txheej txheem knurling pib los ntawm kev kho lub workpiece ntawm lub tshuab dhos lossis lub tshuab knurling tshwj xeeb. Cov cuab yeej knurling muaj ob lub log uas muaj zog steel nrog cov qauv xav tau, uas yog tom qab ntawd nias tawm tsam qhov kev sib hloov ua haujlwm. Raws li lub workpiece tig, cov cuab yeej knurling imprints tus qauv mus rau saum npoo, tsim kom muaj qhov xav tau kev ntxhib los mos.

Yuav ua li cas kom knurling?

Ntawm no yog ib qho kev piav qhia dav dav ntawm yuav ua li cas knurling rau machined qhov chaw:

1.Xaiv txoj cai knurling cuab tam:Knurling cov cuab yeej tuaj nyob rau hauv ntau qhov ntau thiab tsawg thiab cov qauv. Xaiv ib lub cuab yeej uas haum rau qhov xav tau knurl qauv thiab ib feem txoj kab uas hla. Muaj ob txoj hauv kev tseem ceeb ntawm knurling:ib qho taw tes knurling thiab plunge knurling. Ib qho taw tes knurling yuav siv ib lub log los thwj tus qauv rau ntawm qhov chaw ua haujlwm, thaum plunge knurling siv ob lub log los tsim cov qauv ib txhij. Ob txoj kev xav tau kev tswj xyuas meej ntawm cov cuab yeej knurling thiab workpiece kom ntseeg tau tias muaj txiaj ntsig zoo thiab raug.

2.Tuav qhov ntu:Siv atshuab dhos los yog lub tshuab zoo sib xws los tuav qhov chaw ruaj ntseg. Nws yog ib qho tseem ceeb kom paub tseeb tias cov khoom nyob hauv nruab nrab thiab ua kom zoo kom tsis txhob muaj kev sib tw thaum lub sijhawm knurling.

3. Teem lub cuab yeej knurling:Nruab cov cuab yeej knurling xaiv rau ntawm lub tshuab dhos lub cuab yeej. Kho lub cuab yeej kom nws ua rau lub teeb sib cuag nrog qhov chaw ntawm qhov chaw.

4. Siv cov roj nplua nyeem:Siv cov roj los yog roj nplua nyeem rau ntawm qhov chaw kom txo tau kev sib txhuam thiab cov cua sov uas tsim los thaum lub sij hawm knurling.

5.Ua haujlwm knurling:Txuas lub tshuab dhos thiab maj mam pub cov cuab yeej knurling rau hauv ib feem. Cov cuab yeej no yuav tsim ib tus qauv knurl raws li qhov chaw rotates. Nws yog ib qho tseem ceeb uas yuav tsum tau siv lub siab sib xws thiab pub tus nqi kom ua tiav cov qauv knurling zoo ib yam.

6.Nrhiav lub knurling:Tom qab kev ua haujlwm knurling tiav lawm, tshawb xyuas qhov chaw knurled rau txhua qhov tsis xws luag lossis tsis sib xws. Yog tias tsim nyog, ua qhov tsim nyog hloov kho rau cov cuab yeej lossis cov txheej txheem.

7.Clean Parts:Tshem tawm cov roj nplua nyeem lossis cov khib nyiab tawm ntawm qhov chaw knurled kom pom cov qauv knurl tiav.

Nws yog tsim nyog sau cia tias knurling yuav tsum tau precision thiab ua tib zoo saib xyuas kom meej kom ua tiav cov nyhuv xav tau. Tsis tas li ntawd, kev xyaum thiab kev paub dhau los yog qhov tseem ceeb rau kev paub txog cov txheej txheem knurling. Yog tias koj yog tus tshiab rau knurling, xav nrhiav kev taw qhia los ntawm tus kws paub txog tshuab tshuab lossis xa mus rau koj lub tshuab tshwj xeeb thiab cov cuab yeej phau ntawv rau cov lus qhia ntxaws.

Vim li cas knurling tseem ceeb rau machined qhov chaw?

Knurling yog qhov tseem ceeb rau tig qhov chawrau ntau qhov laj thawj. Ua ntej, nws txhim kho kev tuav thiab tuav ntawm lub workpiece, ua kom yooj yim rau kev lis thiab siv ntau yam kev siv. Qhov no yog qhov tseem ceeb tshwj xeeb nrog cov khoom xws li pob qhov rooj, tes tuav, thiab cov cuab yeej, qhov chaw tuav ruaj yog qhov tseem ceeb rau kev nyab xeeb thiab ua haujlwm tau zoo.

Tsis tas li ntawd, knurling txhim kho qhov zoo nkauj ntawmtig qhov chaw, ntxiv cov hniav thiab cov kws tshaj lij kov rau saum npoo. Qhov no yog tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau cov neeg siv khoom thiab cov khoom siv high-end, raws li cov tsos ua lub luag haujlwm tseem ceeb hauv kev ua tau zoo thiab kev nkag siab ntawm cov khoom.

Tsis tas li ntawd, knurling tuaj yeem ua haujlwm rau lub hom phiaj los ntawm kev muab lub ntsej muag rau kev sib txuas lossis tuav lwm yam khoom. Piv txwv li, knurled nto tuaj yeem siv los ua kom ruaj ntseg ntawm cov khoom siv roj hmab, cov ntxig lossis cov hlua khi, ua kom muaj kev ruaj ntseg thiab ruaj ntseg ntawm cov khoom sib txuas.

In precision tig ib feems, knurling feem ntau yog siv ua ke nrog lwm cov txheej txheem machining kom ua tiav qhov yuav tsum tau ua thiab kev ua haujlwm. Los ntawm kev sib txuas knurling nrog tig, milling thiab drilling, cov tuam ntxhab tuaj yeem tsim qhov nyuaj thiab siab-precision qhov uas ua tau raws li qhov yuav tsum tau ua ntawm niaj hnub engineering thiab tsim.

Hauv cov ntsiab lus, knurling yog txheej txheem tseem ceeb hauv kev tsim khoomprecision tig qhov chaw, muab kev tuav zoo dua qub, zoo li qub, thiab kev ua haujlwm. Los ntawm kev ua tib zoo tswj cov txheej txheem knurling thiab xaiv cov qauv tsim nyog thiab cov txheej txheem, cov tuam ntxhab tuaj yeem tsimcov khoom zoouas ua tau raws li cov qauv nruj ntawm kev lag luam niaj hnub. Txawm hais tias yog vim li cas los yog zoo nkauj, knurling plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom tig, ua kom lawv ua tau raws li cov kev xav tau ntawm niaj hnub no ntau haiv neeg thiab xav tau daim ntawv thov.

Post lub sij hawm: Jun-06-2024