Thaum xaiv ib lub vojvoog khoov rauprecision sheet hlau manufacturing, Nws yog ib qho tseem ceeb uas yuav tau xav txog cov kev cai tshwj xeeb ntawm cov txheej txheem tsim khoom thiab cov yam ntxwv ntawm cov ntawv hlau siv. Nov yog qee cov kauj ruam los pab koj xaiv qhov tsim nyog khoov vojvoog rauprecision sheet hlau manufacturing:

1. Kev xaiv cov khoom siv:Xav txog hom ntawv hlau siv, nrog rau nws cov thickness, ductility, thiab elasticity. Cov ntaub ntawv sib txawv tuaj yeem muaj qhov tshwj xeeb khoov lub vojvoog, yog li nws yog ib qho tseem ceeb kom nkag siab txog cov yam ntxwv ntawm cov khoom.

2. Yam tsawg kawg nkaus khoov vojvoog cov lus qhia:Xa mus rau qhov tsawg kawg nkaus khoov vojvoog cov lus qhia los ntawm koj tus neeg muab khoom siv lossis cov lus qhia tshwj xeeb rau koj hom ntawv hlau tshwj xeeb. Cov txheej txheem no yog ua raws li cov khoom ntawm cov khoom siv thiab tseem ceeb heev kom ua tiav cov kev khoov kom zoo yam tsis muaj kev cuam tshuam rau kev ncaj ncees ntawm cov hlau.

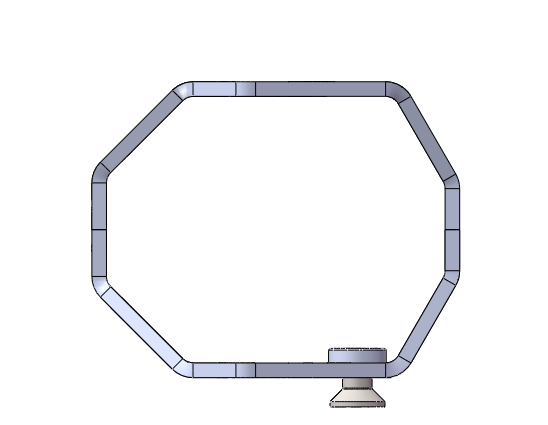

3. Cov cuab yeej thiab khoom siv:Xav txog qhov muaj peev xwm ntawm cov khoom siv khoov thiab cov cuab yeej siv hauv kev tsim khoom. Lub vojvoog khoov yuav tsum phim lub peev xwm ntawm lub tshuab kom paub meej thiab zoo ib yam.

4. Kev kam rau siab thiab qhov raug:Xav txog qhov tseeb ntawm koj qhov project tsim. Qee daim ntawv thov yuav xav tau kev zam nruj dua, uas tuaj yeem cuam tshuam rau kev xaiv lub vojvoog khoov thiab qhov tseeb ntawm cov txheej txheem khoov.

5. Qauv thiab Kev Xeem:Yog ua tau,tsim ib qho qauv lossis kev sim ntsuas los txiav txim siab qhov zoo tshaj plaws khoov vojvoog rau koj cov ntawv tshwj xeeb thiab kev tsim khoom. Qhov no tuaj yeem pab txheeb xyuas cov teeb meem uas muaj peev xwm thiab ua kom lub vojvoog khoov tau xaiv raws li qhov xav tau ntawm qhov project.

6. Tham nrog tus kws tshaj lij kev tsim khoom:Yog tias koj tsis paub meej txog qhov tsim nyog khoov lub vojvoog rau qhov kev ua tiav ntawm cov ntawv hlau tsim, xav txog kev sab laj ib tus kws paub txog cov ntawv hlau fabricator lossis tus engineer uas tshwj xeeb hauvprecision dabtsi yog khoov. Lawv tuaj yeem muab kev nkag siab zoo thiab cov lus qhia raws li lawv cov kev txawj ntse.

HY Metals pab pawg muaj kev txhawb nqa engineering. Peb xav pab thaum koj muaj lus nug hauv koj daim ntawv hlau tsim.

Los ntawm kev xav txog cov xwm txheej no thiab ua raws li cov kauj ruam no, koj tuaj yeem xaiv qhov zoo tshaj plaws khoov vojvoog rauprecision ntawv hlaukev tsim khoom, kom ntseeg tau cov txiaj ntsig zoo thiab raug.

Yog lawm, cov ntawv sib txawv hlau khoov radiu tuaj yeem cuam tshuam rau kev sib dhos ntawm cov khoom tsim thiab cov khoom siv.

Nov yog qee txoj hauv kev sib txawv khoov radii cuam tshuam rau cov txheej txheem sib dhos:

1. Kev sib dhos thiab kev sib dhos:Cov khoom uas muaj qhov sib txawv khoov radii yuav tsis haum zoo lossis ua raws li qhov xav tau thaum sib dhos. Qhov sib txawv khoov radii tuaj yeem ua rau tsis sib xws hauv qhov loj me thiab cov duab geometry, cuam tshuam rau tag nrho cov haum thiab kev sib dhos ntawm lub rooj sib txoos.

2. Vuam thiab koom nrog:Thaum vuam los yog koom nrog cov ntawv hlau nrog qhov sib txawv khoov radii, kev ua tiav ib qho kev sib txuas thiab muaj zog tuaj yeem nyuaj. Qhov sib txawv khoov radii tuaj yeem tsim qhov sib txawv lossis qhov tsis sib xws, ua rau nws nyuaj rau kev ua tiav cov vuam zoo lossis sib koom ua ke.

3. Kev ntseeg ruaj khov:Cov Cheebtsam uas muaj qhov sib txawv khoov radii tuaj yeem pom qhov sib txawv ntawm cov qauv kev ncaj ncees, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas muaj zog thiab ruaj khov yog qhov tseem ceeb. Kev khoov radii tsis sib xws tuaj yeem ua rau tsis sib xws kev ntxhov siab thiab cov ntsiab lus tsis muaj zog hauv kev sib dhos.

4. Aesthetics thiab tiav:Nyob rau hauv cov khoom uas zoo li tseem ceeb, xws li nyob rau hauv cov khoom siv los yog architectural ntsiab, txawv khoov radii yuav ua rau pom inconsistencies thiab nto irregularities uas muaj feem xyuam rau lub zuag qhia tag nrho aesthetics thiab tiav ntawm cov khoom.

Txhawm rau txo cov teeb meem no, nws yog ib qho tseem ceeb uas yuav tsum ua tib zoo npaj thiab tsim cov txheej txheem tsim khoom kom ntseeg tau tias qhov kev xaiv khoov vojvoog yog qhov sib xws thiab sib xws thoob plaws cov khoom uas yuav sib sau ua ke. Tsis tas li ntawd, kev soj ntsuam kom zoo thiab kev ntsuas kev tswj xyuas zoo tuaj yeem pab txheeb xyuas thiab daws txhua qhov teeb meem cuam tshuam txog kev sib dhos uas tshwm sim los ntawm qhov sib txawv ntawm qhov khoov radii ntawm cov ntawv hlau.

HY Hlau muab kev pabcuam kev tsim khoom ib-nres nrog rau cov ntawv hlau fabrication thiab CNC machining, 14 xyoo kev paub thiab 8 tag nrho cov tswv cuab.

Kev tswj tau zoo heev, luv luv turnaround, kev sib txuas lus zoo.

Xa koj RFQ nrog cov duab kos kom ntxaws hnub no. Peb yuav hais rau koj ASAP.

WeChat:ib 09260838

Qhia:+86 15815874097

Email:susanx@hymetalproducts.com

Post lub sij hawm: Aug-12-2024