Muaj qee cov qauv tshwj xeeb lossis cov yam ntxwv uas nyuaj rau kev tsim rausheet hlau qauvqhov chaw:

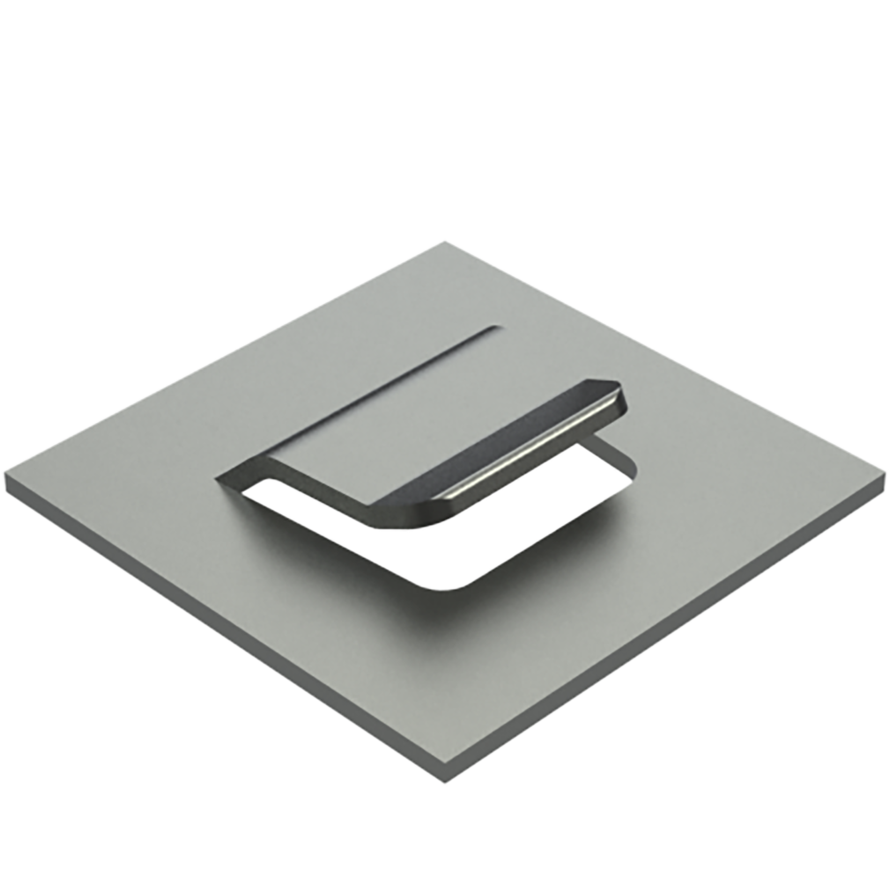

1.Lance (刺破)

In sheet hlau fabrication, ib lub lance yog ib txoj haujlwm uas tsim me me, nqaim txiav los yog slits hauv cov ntawv hlau. Qhov kev txiav tawm no tau ua tib zoo tsim los tso cai rau cov hlau khoov los yog quav raws cov kab ntawm kev txiav. Lance feem ntau yog siv los pab txhawb kev khoov thiab tsim cov duab thiab cov qauv hauv cov ntawv hlau.

Nov yog qee cov ntsiab lus tseem ceeb thiab kev xav txog kev sivlance nyob rau hauv daim ntawv hlau tsim:

Lub hom phiaj:Lub lance yog siv los tsim cov kab uas tau txiav txim siab khoov rau ntawm cov ntawv hlau, yog li ua tiav kev ua haujlwm raug thiab tswj kev khoov. Lawv muaj txiaj ntsig tshwj xeeb rautsim fins, flanges, thiab lwm yam nta uas yuav tsum tau ntse khoov los yog complex geometry.

Kev txiav txim siab tsim:Thaum muab lub Lance rau hauv kev tsim cov ntawv hlau, nws yog ib qho tseem ceeb uas yuav tau xav txog cov khoom tuab, lub kaum sab xis thiab qhov ntev ntawm lub lance, thiab tag nrho cov qauv kev ncaj ncees ntawm ib feem. Lub lance tsim tau zoo pab txo qis kev cuam tshuam thiab xyuas kom meej qhov khoov.

Bending txheej txheem:Lub lance feem ntau yog siv ua ke nrog lub tshuab dabtsi yog khoov lossis lwm yam khoom siv los khoov lub phaj hlau raws li txoj kab txiav. Lub lance muab qhov tseeb khoov taw qhia rau kev ua haujlwm zoo ib yam thiab rov ua haujlwm molding.

Khoom deformation:Thaum lub sij hawmkhoovtxheej txheem, ceev faj yuav tsum tau them rau qhov muaj peev xwm ntawm cov khoom deformation los yog tawg nyob ze ntawm lub lance cutout. Cov cuab yeej tsim nyog thiab khoov cov txheej txheem yog qhov tseem ceeb los txo cov teeb meem no.

Daim ntawv thov: Lance feem ntau yog siv los tsimvaj tse, brackets,chassis Cheebtsamthiab lwm yam ntawv hlau qhov chaw uas yuav tsum tau cov geometries meej thiab complex.

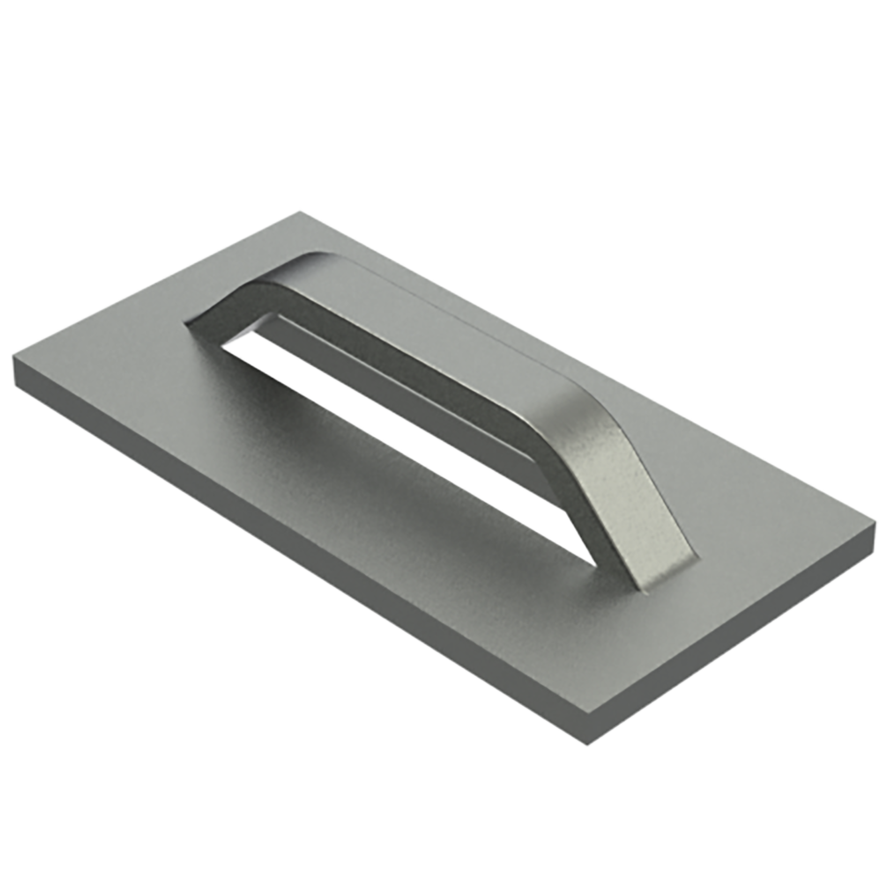

2.Choj (线桥)

In sheet hlau qhov chaw, chojyog tsa ib feem ntawm cov khoom siv, feem ntau siv los tsim txoj hauv kev rau cables lossis xov hlau kom dhau mus. Qhov no feature feem ntau pom nyob rau hauvhluav taws xob enclosures, tswj vaj huam sib luag, thiab lwm yam khoom siv uas yuav tsum tau xaim los ntawm cov ntawv hlau.

Tus choj yog tsim los muab kev sib koom ua ke thiab kev tiv thaiv rau cov cables, tiv thaiv kom tsis txhob raug pinched, puas lossis tangled. Nws kuj pab tswj kom huv si thiab ua haujlwm zoo rau lub rooj sib txoos tag nrho.

Thaum tsim cov kab txuas txuas hauv cov ntawv hlau, ntau yam yuav tsum tau xav txog:

Loj thiab zoo:Tus choj yuav tsum tau tsim kom haum raws li qhov loj thiab tus naj npawb ntawm cov cables uas yuav tsum tau dhau los ntawm nws. Yuav tsum muaj kev tshem tawm thiab qhov chaw txaus kom tsis txhob muaj neeg coob coob thiab ua kom yooj yim rau kev teeb tsa thiab kev saib xyuas cable.

Smooth ntug:Cov npoo ntawm lub tais cable yuav tsum du yam tsis muaj qhov ntse burrs lossis ntxhibqhov chaw tiv thaiv kab mob kev puas tsuaj thaum hla dhau.

Mounting thiab Support:Tus choj yuav tsum tau ruaj khov rau cov ntawv hlau thiab muab kev txhawb nqa txaus rau cov cables. Qhov no tej zaum yuav koom nrog cov brackets ntxiv los yog kev txhawb nqa kom muaj kev ruaj ntseg ntawm tus choj.

EMI / RFI tiv thaiv:Qee zaum, tus choj yuav xav tau kev cuam tshuam hluav taws xob (EMI) lossis xov tooj cua cuam tshuam (RFI) tiv thaiv kev tiv thaiv cable los ntawm kev cuam tshuam sab nraud.

Kev Siv Tau:Kev tsim ntawm tus choj yuav tsum tso cai yooj yim rau kev nkag mus rau cov cables rau kev kho lossis hloov pauv yam tsis tas yuav disassemble tag nrho cov ntawv hlau sib dhos.

Los ntawm kev ua tib zoo xav txog cov xwm txheej no, cov txuas txuas hluav taws xob hauv cov ntawv hlau tuaj yeem tsim tau zoo los muab txoj hauv kev txhim khu kev qha thiab txhim khu kev qha rau cables, yog li pab txhim kho tag nrho kev ua haujlwm thiab ua haujlwm ntev ntawm kev sib dhos.

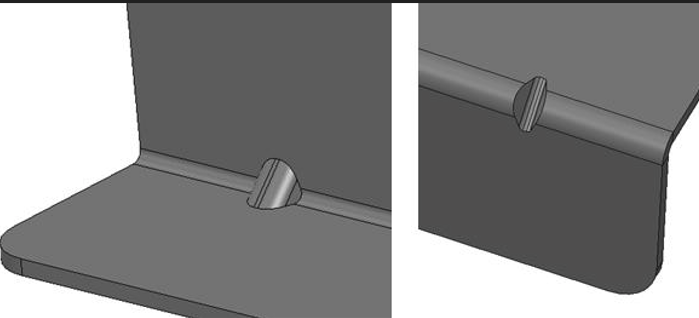

3.Embossingthiab Ribs(凸包和加强筋)

Embossing yuav tsim ib qho kev tsim tsa lossis qauv rau saum npoo ntawm daim hlau. Nws tuaj yeem nyuaj kom ua tiav zoo ib yam thiab txawm tias embossing tsis ua rau deformation lossis warping ntawm thaj chaw ib puag ncig.

Embossing thiab tav yog ob qho tseem ceeb hauv cov ntawv hlau uas siv los txhim kho cov qauv kev ncaj ncees, kev zoo nkauj, thiab kev ua haujlwm ntawm qhov kawg.. Nov yog cov ntsiab lus luv luv ntawm txhua tus:

Embossing (ntaub ntawv):

Embossing yuav tsim ib qho kev tsim tsa los yog qauv ntawm qhov chaw ntawm cov ntawv hlau. Qhov no tuaj yeem ua tiav rau kev kho kom zoo nkauj, los tso saib lub logo lossis cov ntawv nyeem, lossis ntxiv kev ntxhib los mos rau ib feem.

Ntxiv nrog rau kev zoo nkauj, embossing tuaj yeem siv los txhawb cov cheeb tsam tshwj xeeb ntawm cov ntawv hlau, muab lub zog ntxiv thiab rigidity.

Cov txheej txheem embossing feem ntau yog siv cov cuab yeej tshwj xeeb thiab tuag los nias cov qauv xav tau lossis tsim rau hauv cov ntawv hlau.

Ribs(加强筋):

Ribs feem ntau yog siv los txhawb lub tiaj los yog nkhaus daim ntawv hlau, tiv thaiv lawv los ntawm buckling los yog deforming nyob rau hauv load.

Los ntawm kev tsim cov ribs hauv kev tsim, tag nrho qhov hnyav ntawm ib feem tuaj yeem txo qis thaum tswj kev ua haujlwm zoo.

Qhov sib ntxiv ntawm cov tav tuaj yeem txhim kho qhov kev tiv thaiv ntawm kev khoov, torsion, thiab lwm yam kev ntxhov siab.

Ob leeg embossing thiab tav yog cov txheej txheem tseem ceeb hauv cov ntawv hlau sib sau, tso cai rau cov tuam txhab tsim cov khoom uas tsis yog tsuas yog pom kev txaus siab xwb tab sis kuj tseem muaj zog thiab ua haujlwm zoo. Cov yam ntxwv no feem ntau muab tso rau hauv ntau yam khoom, nrog rau cov khoom siv tsheb, cov khoom siv hluav taws xob, cov khoom siv vaj huam sib luag, thiab ntau yam khoom siv.

4.Louvers (百叶风口)

Louvers yog ib hom cua tshuab uas feem ntau siv rau hauv cov ntawv hlau fabrication.Lawv tau tsim los tso cai rau huab cua ntws los thaum tiv thaiv kev nkag ntawm dej, av, lossis lwm yam khib nyiab. Louvers feem ntau yog tsim los ntawm kev txiav los yog xuas nrig ntaus cov kab los yog qhov hauv cov ntawv hlau, thiab tom qab ntawd khoov cov hlau los tsim cov kab ntawm cov fins lossis cov hniav.

Louvers tuaj yeem siv rau ntau yam kev siv, suav nrog HVAC systems, cov khoom siv hauv tsev, cov khoom siv tsheb, thiab cov khoom siv vaj tsev. Lawv feem ntau yog siv los txhim kho cov cua ntws thiab qhov cua hauv cov tsev, tshuab, thiab tsheb, nrog rau kev ua kom zoo nkauj.

Hauv kev tsim cov ntawv hlau, cov louvers feem ntau yog tsim los siv cov cuab yeej tshwj xeeb xws li xuas nrig ntaus, laser txiav tshuab, lossis CNC routers. Kev tsim thiab kev tso kawm ntawm lub louvers yog ua tib zoo xam los xyuas kom meej qhov zoo ntawm airflow thiab functionality.

Louvers tuaj yeem tsim los ntawm ntau yam ntaub ntawv, suav nrog txhuas, hlau, stainless hlau, thiab tooj liab, nyob ntawm seb qhov yuav tsum tau ua ntawm daim ntawv thov. Lawv tuaj yeem raug coated los yog pleev xim rau kom muaj kev tiv thaiv ntxiv tiv thaiv corrosion thiab kom haum rau qhov zoo nkauj ntawm ib puag ncig ib puag ncig.

Zuag qhia tag nrho, louvers yog ib qho tseem ceeb hauv kev tsim cov ntawv hlau, muab ob qho tib si ua haujlwm thiab zoo nkauj hauv ntau yam kev siv.

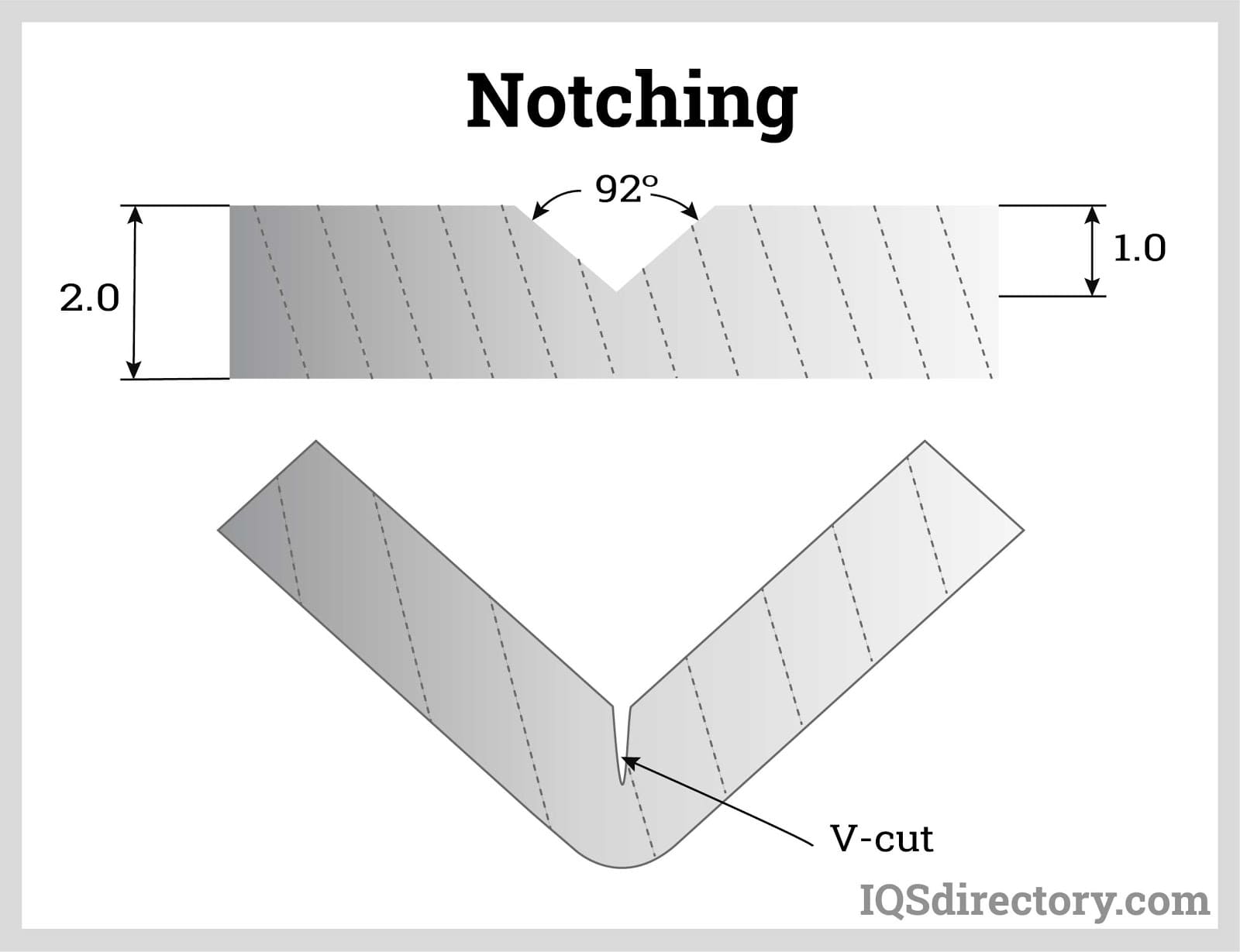

5.Lusthiab Notches(凸耳, 切槽)

Lugs thiab notches yog me me protrusions los yog txiav nyob rau hauv hlau daim hlau siv los ua ke los yog interlocking lub hom phiaj. Nws tuaj yeem nyuaj los tsim cov tab thiab cov ntawv sau uas haum ua ke kom raug thiab ruaj ntseg yam tsis ua rau muaj qhov tsis zoo lossis cov ntsiab lus tsis muaj zog.

Nyob rau hauv cov ntaub ntawv hlau fabrication, lugs thiab notches yog feem ntau siv nta uas pab ntau yam hom phiaj nyob rau hauv lub tsim thiab functionality ntawm cov khoom kawg.

Lugs:

Lugs yog qhov project me me lossis txuas ntxiv ntawm ib daim ntawv hlau uas feem ntau yog siv los txuas lossis tuav lwm yam khoom. Lawv feem ntau siv rau lub hom phiaj mounting, xws li txuas brackets, fasteners, los yog lwm qhov chaw rau cov ntawv hlau. Lugs tuaj yeem tsim los ntawm cov txheej txheem xws li xuas nrig ntaus, drilling, lossis laser txiav, thiab lawv feem ntau khoov lossis tsim rau cov duab uas xav tau los muab qhov chaw ruaj ntseg. Lugs yog qhov tseem ceeb rau kev ua kom muaj kev ncaj ncees thiab kev ruaj ntseg ntawm lub rooj sib txoos zaum kawg.

Notches:

Notches yog indentations los yog cutouts nyob rau hauv daim ntawv hlau uas ua hauj lwm rau ntau yam hom phiaj, xws li haum lwm yam Cheebtsam, muab clearance rau fasteners, los yog tso cai rau khoov los yog tsim ntawm cov hlau. Notches tuaj yeem tsim tau siv cov txheej txheem xws li laser txiav, shearing, lossis xuas nrig ntaus, thiab lawv feem ntau tsim los rau qhov ntev kom paub meej kom haum thiab ua haujlwm. Notches yog qhov tseem ceeb rau kev ua kom cov ntawv hlau kom haum rau hauv cov rooj sib txoos, ua ke nrog lwm cov khoom, los yog pab txhawb kev khoov thiab shaping ntawm cov hlau yam tsis muaj kev cuam tshuam nws cov qauv kev ntseeg.

Ob lub lugs thiab notches yog cov ntsiab lus tseem ceeb hauv kev tsim cov ntawv hlau, thiab lawv yuav tsum tau ua tib zoo saib xyuas hauv kev tsim thiab tsim cov txheej txheem los xyuas kom meej tias lawv ua tau raws li qhov tshwj xeeb ntawm cov khoom kawg. Cov yam ntxwv no ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm tag nrho, kev sib dhos, thiab kev ua haujlwm ntawm cov ntawv hlau thiab cov khoom sib dhos.

Tag nrho cov yam ntxwv tshwj xeeb no yog qhov nyuaj hauv kev tsim cov ntawv hlau tshwj xeeb hauv cov ntawv hlau prototyping txheej txheem yam tsis muaj kev tsim cov cuab yeej. Lawv xav tau kev saib xyuas kom zoo thiab kev txawj ntse hauv daim ntawv hlau prototyping kom ntseeg tau tias lawv tau ua tiav thiab ua tau zoo. HY Hlau ntawm no yog cov kws tshaj lij hauv txhua cov qauv tawv thiab nta. Peb tau ua ntau qhov zoo meej nrog cov yam ntxwv zoo li no.

Post lub sij hawm: Mar-22-2024