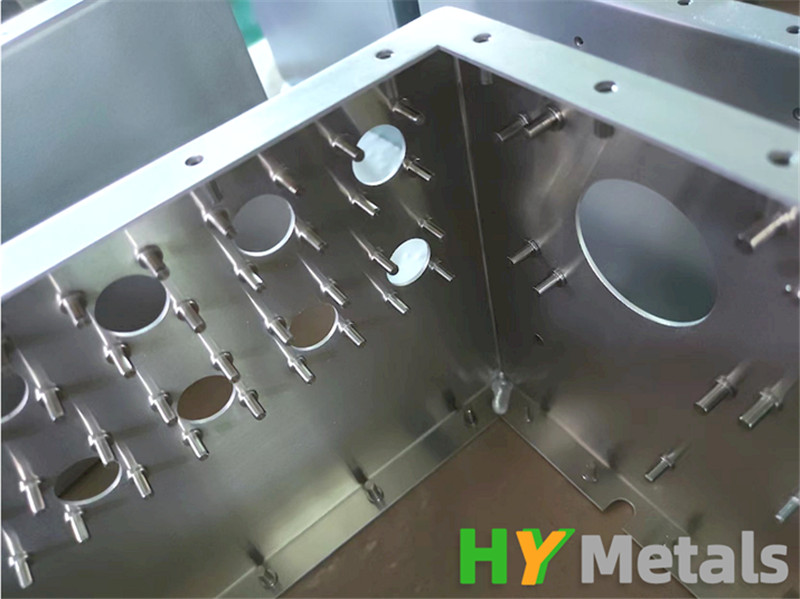

Cov kev pabcuam no feem ntau siv los tsim cov qauv, cov khoom siv, thiab cov khoom siv rau ntau yam kev lag luam, suav nrog tsheb, aerospace, kev kho mob, thiab kev tsim kho. Sheet hlau vuam thiab sib dhos tuaj yeem siv los tsim cov khoom ntawm txhua qhov loj thiab qhov nyuaj. Cov kws tshaj lij uas tshwj xeeb hauv cov khoom siv tes ua no siv cov khoom siv vuam zoo thiab cov txheej txheem los xyuas kom muaj zog, ruaj khov weld uas ua tau raws li cov neeg siv khoom tshwj xeeb. Lawv kuj xav txog hom hlau siv thiab ib puag ncig uas cov khoom yuav raug siv.

Sheet Hlau Fabrication Txheej Txheem:Txiav,Khoov los yog tsim, Tappinglos yogRiveting,Vuam thiabKev sib dhos.

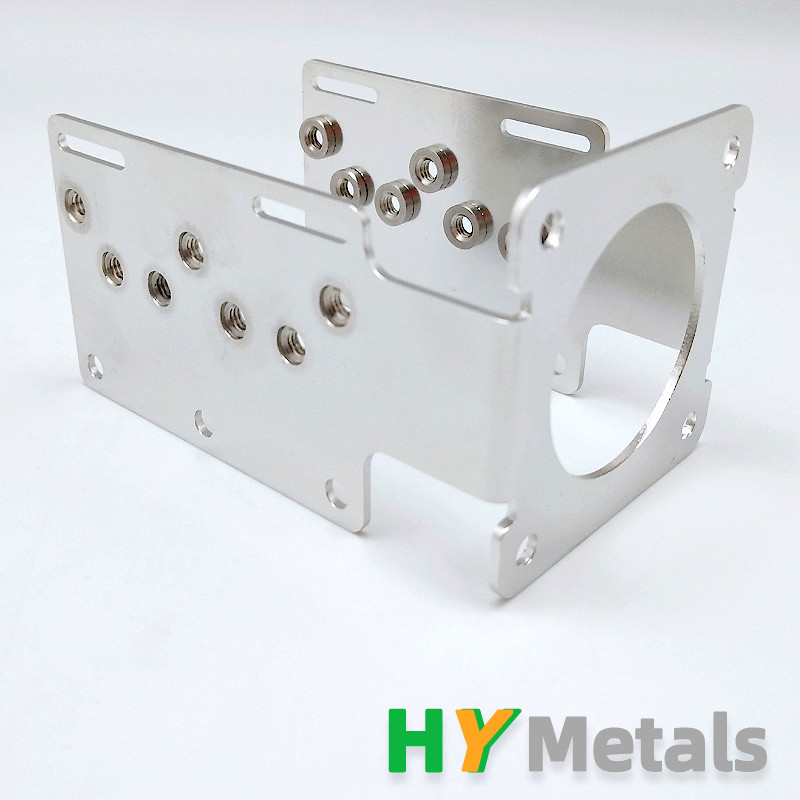

Sheet hlau sib dhos yog cov txheej txheem tom qab txiav thiab khoov, qee zaum nws yog tom qab txheej txheej txheem. Peb feem ntau sib sau ua ke los ntawm riveting, vuam, nias haum thiab tapping rau ntsia hlau lawv ua ke.

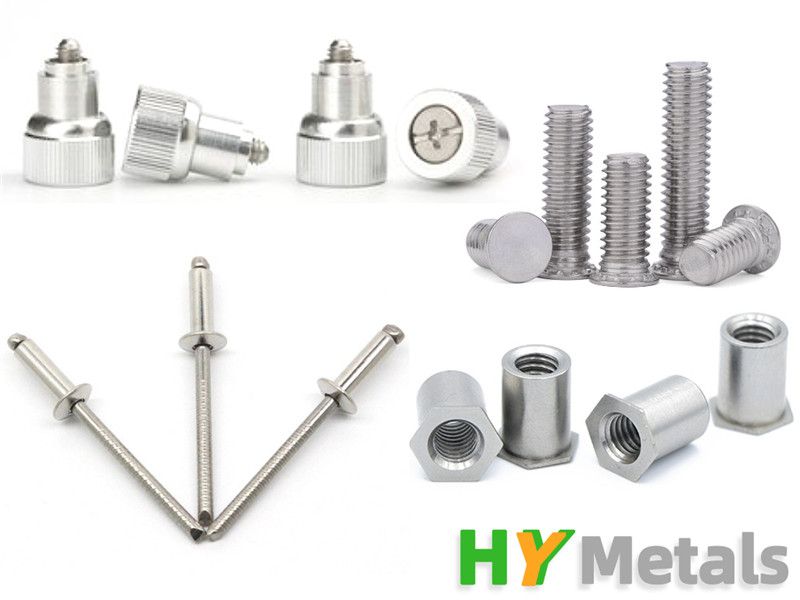

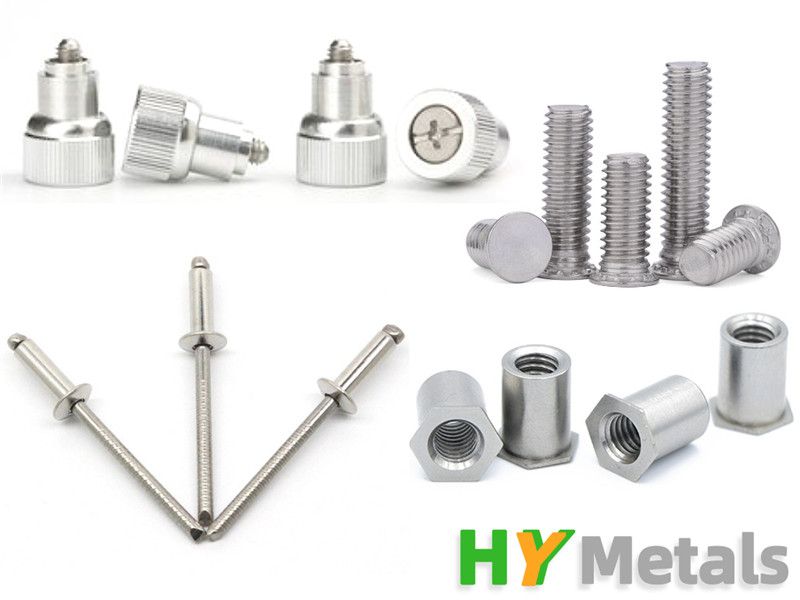

Tapping thiab Riveting

Cov xov yog ua lub luag haujlwm tseem ceeb hauv cov rooj sib txoos. Muaj 3 txoj hauv kev kom tau cov xov: Tapping, riveting, nruab coils.

1.Tapping xov

Tapping yog txheej txheem ua cov xov hauv qhov rau cov ntawv hlau lossis CNC machined qhov chaw nrog kais tshuab thiab cov cuab yeej siv. Nws yog dav siv rau qee cov khoom tuab thiab tawv xws li steel thiab stainless hlau qhov chaw.

Rau nyias hlau los yog cov ntaub ntawv mos xws li txhuas thiab yas, riveting thiab nruab coils yuav ua hauj lwm zoo dua.

2.Riveting ceev thiab Standoffs

Riveting yog qhov yooj yim tshaj plaws thiab feem ntau siv los ua ke txoj hauv kev ua cov ntawv hlau.

Riveting tuaj yeem muab cov xov ntev thiab muaj zog dua li tapping rau nyias hlau phaj

Muaj ntau cov txiv ntseej, screws thiab standoffs rau riveting. Koj tuaj yeem tau txais tag nrho cov qauv loj PEM kho vajtse thiab qee qhov MacMaster-Carr kho vajtse los ntawm HY Hlau rau koj lub rooj sib txoos.

Rau qee cov khoom siv tshwj xeeb uas peb tsis tuaj yeem muab hauv khw hauv zos, koj tuaj yeem muab rau peb los ua ke.

3. Txhim kho Heli-coil insert

Rau qee cov ntaub ntawv tuab tab sis mos zoo li cov yas machined qhov chaw, peb feem ntau nruab Heli-coil inserts rau hauv machined qhov kom tau cov xov rau kev sib dhos.

Nias Fit

Xovxwm haum haum rau qee tus pins thiab ncej sib dhos, thiab siv dav hauv cov khoom siv, qee zaum xav tau hauv cov ntawv hlau.

Vuam

Vuam yog lwm txoj kev siv los ua ke hauv cov ntawv hlau fabrication. Vuam tuaj yeem ua rau ntau qhov sib koom ua ke kom muaj zog.

HY Hlau tuaj yeem ua laser vuam, Argon-arc vuam thiab carbon dioxide arc vuam.

Raws li cov hlau vuam ua haujlwm theem, nws tau muab faib ua qhov chaw vuam, vuam puv, dej pov thawj vuam.

Peb tuaj yeem ua tau raws li koj qhov yuav tsum tau ua ntawm hlau vuam rau koj cov rooj sib txoos.

Qee zaum, peb yuav txhuam cov vuam cov cim kom tau ib qho chaw du ua ntej txheej.