Kev cai precision CNC machined Titanium qhov chaw nrog txhaj tshuaj tigaround

Nyuaj hauvCNCmachining thiab anodizing ntawm titanium alloy qhov chaw

CNC machiningntawm titanium alloys nthuav qhia cov txheej txheem tshwj xeeb ntawm cov kev cov nyom vim yog cov khoom siv los ntawm cov khoom siv. Titanium paub txog nws lub zog-rau-qhov hnyav piv, kev tiv thaiv corrosion, thiab biocompatibility, ua rau nws yog qhov kev xaiv nrov rau aerospace, kev kho mob, thiab kev siv tsheb. Txawm li cas los xij, cov yam ntxwv zoo ib yam kuj ua rau cov txheej txheem machining nyuaj.

Kev Sib Tw

1. Tool Hnav:Titanium alloys paub tias yog abrasive, ua rauceev cov cuab yeej hnav. Titanium lub zog siab txhais tau tias cov cuab yeej txiav yuav tsum tau ua los ntawm cov khoom siv siab heev xws li carbides lossis ceramics kom tiv taus cov kev ntxhov siab cuam tshuam. Txawm hais tias nrog cov ntaub ntawv no, cov cuab yeej lub neej tuaj yeem luv dua li thaum ua cov hlau softer.

2. Thaum tshav kub kub:Titanium muaj cov thermal conductivity tsawg, uas txhais tau hais tias cov cua sov tsim thaum lub sij hawm ua tsis dissipate sai li sai tau. Qhov no ua rau thermal deformation ntawm lub workpiece thiab txiav cov cuab yeej, ua rau tsis zoo nto tiav thiab qhov tsis raug. Cov tswv yim ua kom txias zoo, xws li kev siv cov tshuab cua txias siab, yog qhov tseem ceeb rau kev txo qhov teeb meem no.

3. Chip Tsim:Txoj kev titanium chips tsim thaum lub sij hawm machining tuaj yeem ua rau muaj teeb meem. Tsis zoo li cov hlau softer uas tsim cov chips tas mus li, titanium feem ntau tsim cov chips luv luv uas tuaj yeem ua tangled nrog cov cuab yeej lossis cov khoom ua haujlwm, ua rau cov txheej txheem machining nyuaj ntxiv.

4. Machining Parameters:Xaiv qhov raug txiav ceev, pub tus nqi thiab qhov tob ntawm kev txiav yog qhov tseem ceeb heev. Cov kev ntsuas uas hnyav dhau tuaj yeem ua rau cov cuab yeej tsis ua haujlwm, thaum qhov chaw uas muaj kev saib xyuas ntau dhau tuaj yeem ua rau lub tshuab ua haujlwm tsis zoo thiab lub sijhawm ntau lawm. Nrhiav qhov sib npaug zoo tshaj plaws yuav tsum muaj kev paub dhau los thiab kev sim.

5. Workpiece tuav:Titanium muaj qhov qis qis ntawm elasticity, uas txhais tau hais tias nws yuav deform nyob rau hauv siab, ua rau workpiece tuav ib qho kev sib tw. Tshwj xeeb fixtures thiab clamping txoj kev yog feem ntau yuav tsum tau los xyuas kom meej qhov chaw nyob ruaj khov thaum lub sij hawm machining, uas yuav ntxiv complexity thiab nqi rau cov txheej txheem.

Kev sib tw Anodizing

Tom qabCNCmachining tiav, anodizing titanium alloy ntxiv nyuaj rau kev tsim khoom.Anodizingyog cov txheej txheem electrochemical uas txhim khu kev tiv thaiv corrosion thiab muab qhov zoo nkauj tiav. Txawm li cas los xij, anodizing titanium tuaj nrog nws cov teeb meem nyuaj.

1. Kev Npaj Nto:Qhov saum npoo ntawm titanium yuav tsum tau ua tib zoo npaj ua ntej anodizing. Txhua yam kab mob, xws li roj lossis cov khoom seem, tuaj yeem ua rau tsis zoo adhesion ntawm txheej anodized. Qhov no feem ntau xav tau cov txheej txheem ntxuav ntxiv, xws li ntxuav ultrasonic lossis tshuaj etching, uas ua rau lub sijhawm ntau lawm thiab tus nqi.

2. Anodizing txheej txheem tswj:Cov txheej txheem anodizing ntawm titanium yog rhiab rau ntau yam tsis muaj, nrog rau qhov voltage, kub thiab electrolyte muaj pes tsawg leeg. Ua kom tiav cov txheej txheem anodized yuav tsum muaj kev tswj xyuas meej ntawm cov kev hloov pauv no. Kev hloov pauv tuaj yeem ua rau cov xim tsis sib xws thiab tuab, uas tsis tuaj yeem lees txais hauv cov ntawv thov siab.

3. Xim Consistency:Anodized titanium tuaj yeem tsim ntau yam xim nyob ntawm qhov tuab ntawm txheej anodized. Txawm li cas los xij, ua tiav cov xim zoo ib yam thoob plaws ntau qhov chaw tuaj yeem nyuaj vim qhov txawv ntawm qhov ua tiav thiab tuab. Qhov kev tsis sib haum xeeb no tuaj yeem ua teeb meem rau cov ntawv thov uas qhov kev zoo nkauj zoo nkauj yog qhov tseem ceeb.

4. Kev kho tom qab anodizing:Tom qab anodizing, kev kho mob ntxiv yuav tsum tau txhim kho kev ua haujlwm ntawm txheej anodized. Cov no yuav suav nrog cov txheej txheem sib khi, uas tuaj yeem ua rau muaj kev ua haujlwm nyuaj ntxiv thiab ua rau lub sijhawm ntau lawm.

Hauv kev xaus

CNC machining thiab tom qab anodizing ntawm titanium alloys yog cov txheej txheem nyuaj uas yuav tsum muaj kev paub tshwj xeeb, khoom siv thiab thev naus laus zis. Machining-hais txog cov teeb meem, xws li cov cuab yeej siv, kev tsim hluav taws xob thiab kev tsim cov nti, ua ke nrog cov complexities ntawm anodizing, hais txog qhov yuav tsum tau ua tib zoo npaj thiab ua tiav. Raws li qhov kev thov rau cov khoom siv titanium ua tau zoo txuas ntxiv mus ntxiv thoob plaws kev lag luam, kev kov yeej cov teeb meem no yog qhov tseem ceeb rau cov tuam txhab lag luam txhawm rau ua kom tau raws li cov qauv nruj thiab kev ua tau zoo.

HY Hlau yog ib tug kws tshaj lij nyob rau hauv CNC machining nrog ntau tshaj 14 xyoo kev paub, peb machined ntau ntawm Titanium qhov chaw nrog high precision thiab zoo zoo.

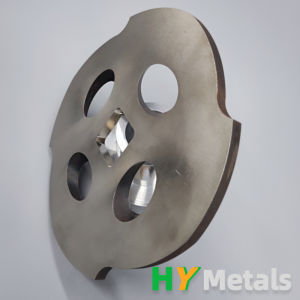

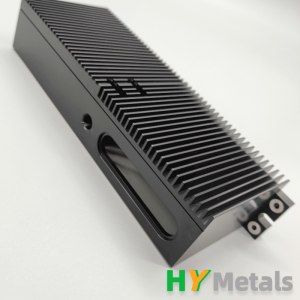

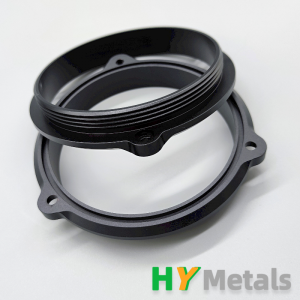

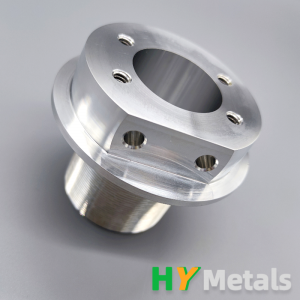

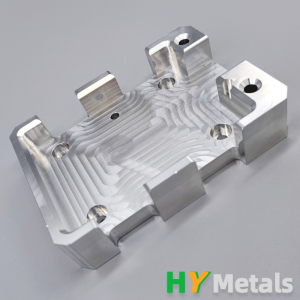

Nov yog qee qhov tuaj txog tshiab ntawmCNC machined Titanium qhov chawua los ntawm HY Hlau.

HY Hlaumuabib-nreskev pabcuam kev tsim khoom suav nrogsheet hlau fabrication thiabCNC machining, 14 xyoo kev paub thiab8 tag nrho cov khoom siv.

Zoo heevZootswj,luvkev hloov pauv,zoo heevkev sib txuas lus.

Xa koj RFQ nrogcov duab kos duab ntxawshnub no. Peb yuav hais rau koj ASAP.

WeChat:ib 09260838

Qhia:+86 15815874097

Email:susanx@hymetalproducts.com