Ib qho Kev Cai Sheet Hlau Bracket Muaj Precision CNC Machining thaj chaw ntawm ntau qhov chaw

Ntawm HY Metals, peb zoo siab rau peb14 xyoo ntawm kev paubthiab kev cog lus kom xa cov khoom zoo tshaj plawskev tsim khoomkev daws teeb meem. Peb cov kws tshaj lij nyob hauvprecision ntawv hlaukev tsim khoomthiabCNC machining, thiab peb tau cog lus los muab peb cov neeg siv khoom nrog cov khoom zoo tshaj plaws hauv chav kawm uas ua tau raws li lawv cov lus qhia meej.

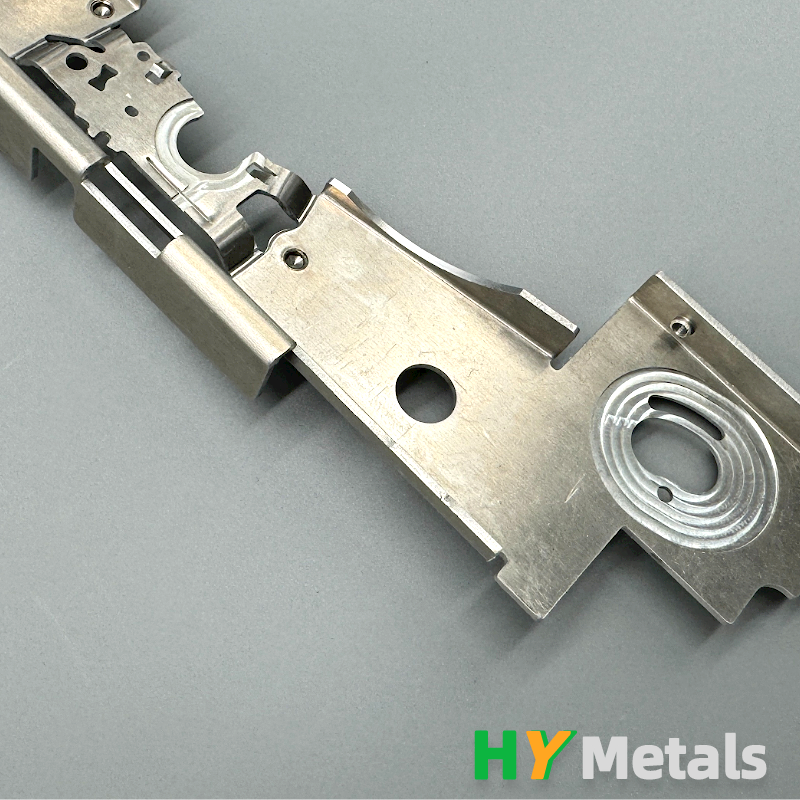

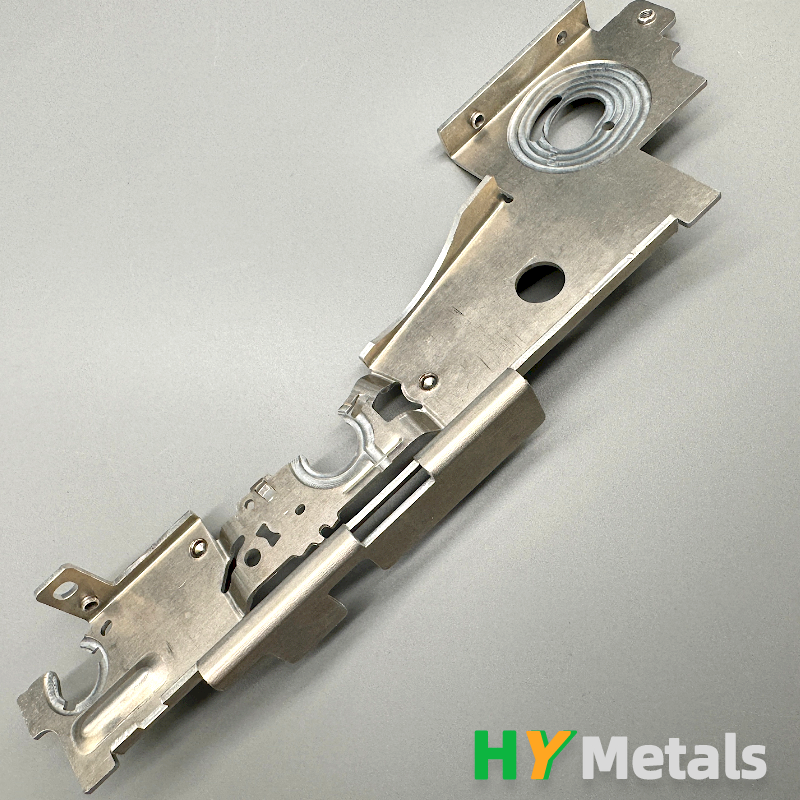

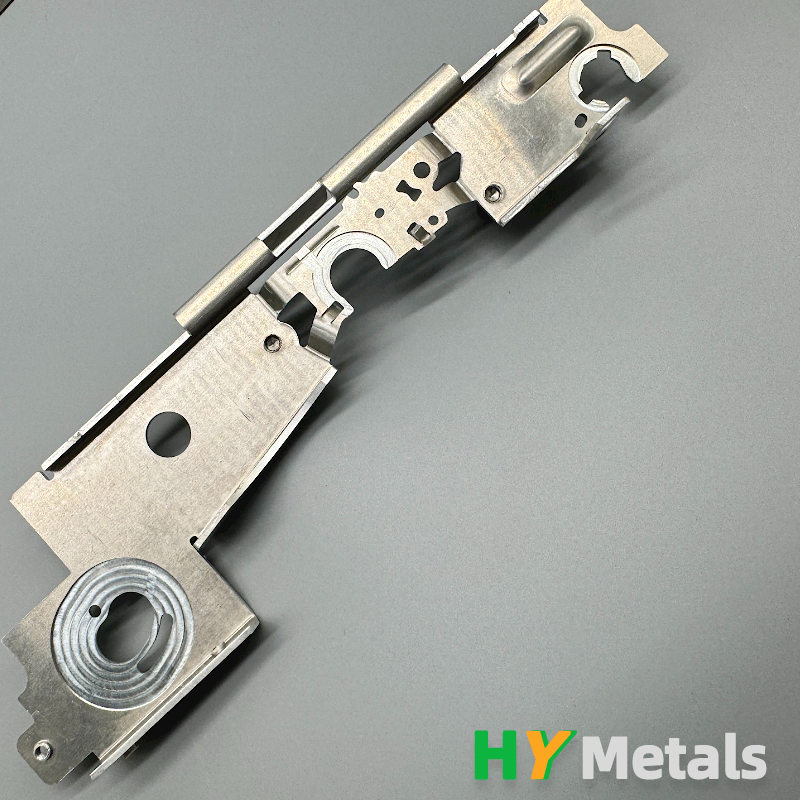

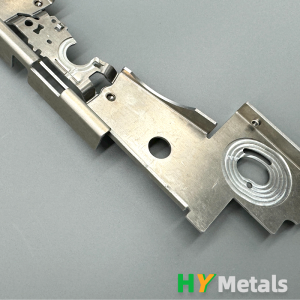

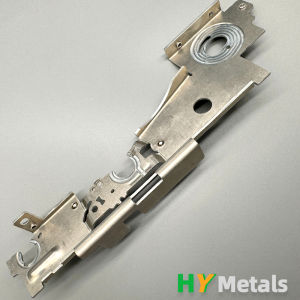

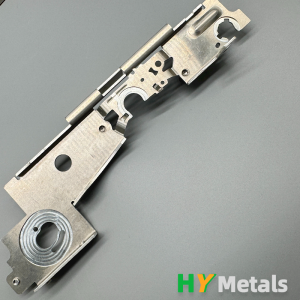

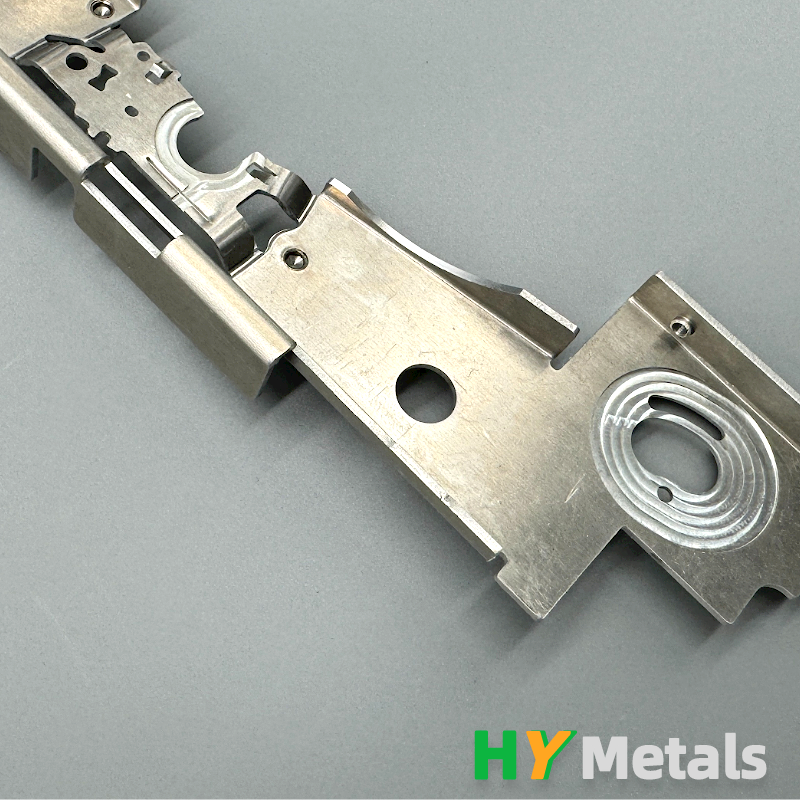

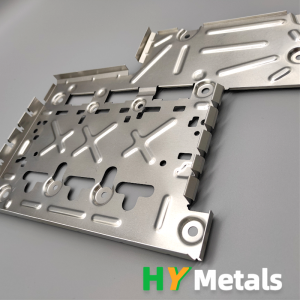

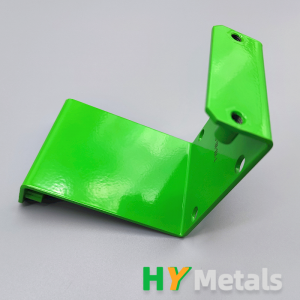

Ib qhov project tsis ntev los no qhia peb lub peev xwm koom nrog kev tsim khoomkev cai sheet hlau qhov chawua los ntawm Al5052 rauautomotive brackets. Cov brackets undergo ib tug series ntawm cov txheej txheem xws li laser txiav, dabtsi yog khoov thiab riveting, ua ntej yuav tsum tau precision machining nyob rau hauv plaub qhov chaw tshwj xeeb los tsim cov kauj ruam voj voog. Qhov kev ua no yog qhov tseem ceeb los hloov cov khoom siv hluav taws xob mus rau theem tom ntej ntawm kev sib dhos.

Qhov kev sib tw ntawm kev tswj xyuas machining tolerances tom qab khoov yog ib qho teeb meem tshwm sim hauv kev lag luam ntawv hlau. Tsis zoo li CNC machining, qhov tolerances ntawm cov ntawv hlau qhov chaw tsis nruj heev, thiab tom qab khoov, nws yog ib qho nyuaj rau kev ruaj ntseg rau lub tshuab CNC kom meej qhov chaw. Txawm li cas los xij, ntawm HY Metals, peb muaj kev txawj ntse thiab thev naus laus zis los kov yeej cov kev cov nyom no thiab ua tiav cov txiaj ntsig zoo dua.

Kev ruaj ntseg ntawm cov ntawv hlau ntawm CNC tshuab tuaj yeem nyuaj, tab sis muaj ntau cov txheej txheem thiab cov kev xav tau uas tuaj yeem pab ua kom nruj machining kam rau ua.

1. Ceev ceev kom zoo: Siv clamps, vises, los yog kev cai fixtures los tuavsheet hlau qhov chawruaj ntseg nyob rau hauv qhov chaw. Thaum tsim lub fixture, xav txog cov khoom thickness, zoo, thiab muaj peev xwm deformation thaum ua.

2. Lub puab tsaig muag:Yog tias siv lub vise, xav txog kev siv lub puab tsaig muag kom tiv thaiv kev puas tsuaj lossis deformation ntawm cov ntawv hlau. Mos lub puab tsaig tuaj yeem raug machined kom phim cov contours ntawm ib feem, muab kev txhawb nqa zoo dua thiab txo qis kev co.

3. Cov qauv kev txhawb nqa:Rau qhov loj dua lossis ntau dua cov ntawv hlau, xav txog kev siv cov qauv kev txhawb nqa lossis cov khoom siv ntxiv kom txo qis deflection thaum lub sijhawm ua haujlwm.

4. Cov ntsiab lus siv:Tsim kom muaj cov ntsiab lus tseeb ntawm cov ntawv hlau los xyuas kom meej qhov chaw thiab kev sib haum xeeb thaum ua. Qhov no yog ib qho tseem ceeb rau kev tswj kom nruj tolerances.

5. Clamping zoo:Tsim kom muaj lub tswv yim clamping uas sib npaug faib lub zog clamping hla ib feem kom txo qis deformation. Xav txog kev siv cov clamps qis lossis ntug clamps kom tsis txhob cuam tshuam nrog cov cuab yeej txiav.

6. Tool txoj kev optimization:Siv CAM software los tsim cov cuab yeej cuab tam uas txo qis kev vibration thiab cov cuab yeej deflection, tshwj xeeb tshaj yog thaum machining nyias los yog muag cov ntawv hlau.

7. Kev tshuaj xyuas thiab kev tawm tswv yim:Siv cov txheej txheem tshuaj xyuas zoo los xyuas qhov tseeb ntawm cov yam ntxwv machining. Siv cov lus tawm tswv yim los ntawm kev tshuaj xyuas cov txiaj ntsig los kho cov khoom siv kho mob thiab cov tswv yim ua haujlwm rau kev ua haujlwm yav tom ntej.

Los ntawm kev daws cov teeb meem no, cov tuam ntxhab tuaj yeem txhim kho qhov raug thiab sib xws ntawmCNC machining ntawm cov ntawv hlau qhov chaw, thaum kawg kom ntseeg taunruj tolerance ua tiav.

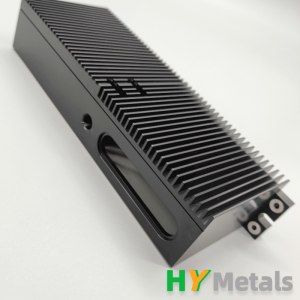

Nrog ib pab neeg ntawm ntau tshaj 350 tus neeg ua haujlwm tau txais kev cob qhia zoo thiab cov chaw ua haujlwm hauv xeev tau nruab nrog ntau dua 500 lub tshuab, peb muaj peev xwm tuav tej yaam num ntawm txhua qhov loj. Txawm hais tias nws yog ib qho qauv tsim los yog ib qho kev tsim tawm ntau txhiab, peb tau cog lus los muab cov khoom zoo tshaj plaws rau ntau yam kev lag luam.

Peb txoj kev mob siab rau kev ua tau zoo thiab kev mloog zoo rau kev nthuav dav yog pom nyob rau hauv kev ua tiav ntawm koj lub tsheb bracket project. Txawm hais tias qhov nyuaj ntawm cov txheej txheem tom qab khoov, peb xyuas kom meej tias cov ntawv hlau tiav tiav ua tau raws li cov qauv siab tshaj plaws ntawm qhov tseeb thiab zoo.

Thaum koj xaiv HY Hlau rau koj cov kev xav tau kev tsim khoom, koj tuaj yeem cia siab tias:

1. Precision sheet hlau raug thiab CNC machining kev txawj ntse

2. Pab neeg mob siab rau muab cov khoom zoo

3. Muaj peev xwm ua haujlwm ntawm txhua qhov loj me, los ntawm kev tsim qauv mus rau ntau lawm

4. Ua tib zoo saib xyuas kom meej thiab mob siab rau kom ua tau raws li koj qhov tshwj xeeb

Txawm koj xav tauprecision sheet hlau qhov chaw, sheet hlau prototypes, precision machining or kev cai tsim kev daws teeb meem, HY Hlau yog koj tus khub ntseeg siab. Hu rau peb hnub no los tham txog koj qhov project xav tau thiab paub qhov txawv ntawm peb qhov kev txawj ntse thiab kev mob siab rau hauv kev xa cov txiaj ntsig tshwj xeeb.